Table of Contents

Advertisement

Owner's Manual

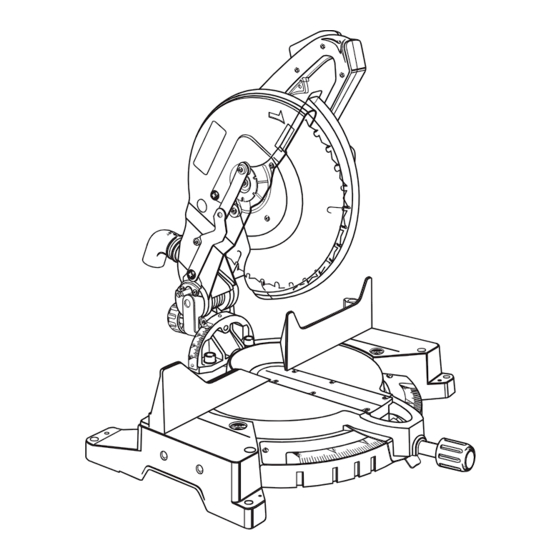

12 in. COMPOUND

MITER SAW

Double Insulated

Model No.

315.212120

Save this manual for

future reference.

CAUTION:

Read and follow

all Safety Rules and Operating

Instructions before first use of

this product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

972000-557

9-99

• Safety

• Features

• Adjustments

• Operation

• Maintenance

• Parts List

NRTL/C

Advertisement

Table of Contents

Summary of Contents for Craftsman 315.212120

- Page 1 Safety Rules and Operating • Adjustments Instructions before first use of • Operation this product. • Maintenance Customer Help Line: 1-800-932-3188 • Parts List Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA Visit the Craftsman web page: www.sears.com/craftsman 972000-557 NRTL/C 9-99...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Table of Contents ............................2 Warranty and Introduction ..........................2 Rules For Safe Operation ........................... 3-6 Glossary ................................. 6 Product Specifications and Unpacking ......................7 Labels ................................8 Loose Parts and Tools Needed ........................9 Features ..............................10-12 Adjustments ............................. -

Page 3: Rules For Safe Operation

RULES FOR SAFE OPERATION The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the explanations with them, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures. - Page 4 RULES FOR SAFE OPERATION (Continued) USE THE PROPER EXTENSION CORD. Make function. Check for alignment of moving parts, sure your extension cord is in good condition. binding of moving parts, breakage of parts, When using an extension cord, be sure to use mounting and any other conditions that may one heavy enough to carry the current your affect its operation.

- Page 5 Lock the miter table by securely tightening the WARNING: When servicing use only identical miter lock handle. Lock the saw arm (bevel Craftsman replacement parts. Use of any other function) by securely tightening the bevel lock parts may create a hazard or cause product knob.

-

Page 6: Glossary

RULES FOR SAFE OPERATION (Continued) ALWAYS STAY ALERT! Do not allow familiarity MAKE SURE THE WORK AREA HAS AMPLE (gained from frequent use of your saw) to cause LIGHTING to see the work and that no obstruc- a careless mistake. ALWAYS REMEMBER that tions will interfere with safe operation BEFORE a careless fraction of a second is sufficient to performing any work using your saw. -

Page 7: Product Specifications And Unpacking

PRODUCT SPECIFICATIONS Blade Diameter 12 in. Cutting Capacity with Miter at 0°/Bevel 0°: Blade Arbor 1 in. max width x resulting height 7-7/8 in. x 2-1/2 in. No Load Speed 4000 RPM Maximum Cutting Capacity with Miter at 45°/Bevel 0°: Rating 120 Volts, 60 Hz-AC Only max width x resulting height... -

Page 8: Labels

• Para su propia seguridad, lea el manual del usuario antes de usar la sierra ingletadora. 12 inch Compound Miter Saw DOUBLE INSULATED 4,000 RPM 120 VOLTS 60 Hz AC ONLY 15 A WARNING: WHEN SERVICING, USE ONLY IDENTICAL CRAFTSMAN REPLACEMENT PARTS. MODEL 315.212120 SER. NO. MADE IN TAIWAN NRTL/C SEARS, ROEBUCK AND CO. -

Page 9: Loose Parts And Tools Needed

LOOSE PARTS LIST The following items are included with your Compound Miter Saw: Saw Blade - 12 in. 5 mm Hex Key Wrench Miter Lock Handle 6 mm Hex Key Wrench Dust Guide 10 mm Hex Key Wrench Blade Wrench Owner's Manual BLADE WRENCH 10 mm HEX KEY... -

Page 10: Features

FEATURES KNOW YOUR COMPOUND MITER CUTTING CAPACITIES ° When the miter angle (miter table) is set at 0 ° See Figure 3. the bevel angle is set at 0 Before attempting to use your saw, familiarize yourself Your saw will cut materials up to: with all operating features and safety requirements. - Page 11 FEATURES CARRYING HANDLE SPINDLE LOCK BUTTON See Figure 4. See Figure 5. For convenience when carrying or transporting your A spindle lock button has been provided for locking miter saw from one place to another, a carrying the spindle which keeps the blade in your saw from handle has been provided on top of the saw arm as rotating.

- Page 12 FEATURES POSITIVE STOPS ON MITER TABLE 30 in. Positive stops have been provided at 0°, 15°, 22-1/2°, 4-1/8 in. 21-3/4 in. 31.62°, and 45° on both the left and right side of the miter table. 3-9/16 in. BEVEL LOCK KNOB The bevel lock knob securely locks your compound 20 in.

-

Page 13: Adjustments

ADJUSTMENTS WARNING: To prevent accidental starting that TO INSTALL BLADE could cause possible serious personal injury, See Figures 10, 11, and 12. assemble all parts to your saw before connecting it to power supply. Saw should never be WARNING: A 12 in. blade is the maximum connected to power supply when you are blade capacity of your saw. - Page 14 ADJUSTMENTS LOWER ARROW Wipe a drop of oil onto inner blade washer and BLADE GUARD outer blade washer where they contact the blade. PHILLIPS SCREW WARNING: If inner blade washer has been removed, replace it before placing blade on BLADE BOLT COVER spindle.

- Page 15 ADJUSTMENTS Note: Many of the illustrations in this manual show FENCE only portions of your compound miter saw. This is FRAMING SQUARE intentional so that we can clearly show points being MITER TABLE made in the illustrations. Never operate your saw without all guards securely in place and in good operating condition.

- Page 16 ADJUSTMENTS FENCE Using a 6 mm hex key, loosen the socket head screws securing the fence. See Figure 16. Adjust the fence left or right until the framing square and FRAMING zero clearance throat plate are parallel. SQUARE Retighten the screws securely and recheck the fence-to-table alignment.

- Page 17 ADJUSTMENTS The edge of the square and the saw blade should Loosen bevel lock knob and set saw arm at 0° be parallel as shown in figure 17. bevel (blade set 90° to miter table). Tighten bevel lock knob. If the front or back edge of the saw blade angles away from the square as shown in figures 18 and Place a combination square against the miter 19, adjustments are needed.

- Page 18 ADJUSTMENTS PIVOT ADJUSTMENTS FENCE Note: These adjustments were made at the factory COMBINATION and normally do not require readjustment. SQUARE TRAVEL PIVOT ADJUSTMENT The saw arm should rise completely to the up position by itself. If the saw arm does not raise by itself or if there is play in the pivot joints, have saw repaired by a qualified service technician at your nearest Sears store to avoid risk of personal injury.

-

Page 19: Adjustments

ADJUSTMENTS WARNING: Before starting any cutting operation, clamp, bolt or nail your compound miter saw to a workbench. Never operate your DEPTH STOP miter saw on the floor or in a crouched position. ADJUSTMENT Failure to heed this warning can result in serious SCREW personal injury. -

Page 20: Operation

OPERATION Slowly lower the blade into and through the workpiece. See Figure 26. Release the switch trigger and allow the saw blade to stop rotating before raising the blade out of workpiece. Wait until the electric brake stops blade from turning before removing the workpiece from the miter table. - Page 21 OPERATION WARNING: BEVEL CUT To avoid serious personal injury, keep your hands outside the no hands zone; at least 3 in. from blade. Never perform any cutting operation freehand (without holding workpiece against the fence). The blade could grab the workpiece if it slips or twists.

- Page 22 OPERATION TO MAKE A COMPOUND CUT WITH Recheck miter angle setting. Make a test cut in scrap material. YOUR MITER SAW: Place the workpiece flat on the miter table with Pull out the lock pin and lift saw arm to its full one edge securely against the fence.

- Page 23 OPERATION Before turning on the saw, perform a dry run of the cutting operation just to make sure that no problems will occur when the cut is made. Grasp the saw handle firmly, press the lock-off tab down, then squeeze the switch trigger. Allow sev- eral seconds for the blade to reach maximum speed.

- Page 24 OPERATION CUTTING COMPOUND MITERS To aid in making the correct settings, the compound angle setting chart below has been provided. Since com- pound cuts are the most difficult to accurately obtain, trial cuts should be made in scrap material, and much thought and planning made, prior to making your required cut.

- Page 25 OPERATION CUTTING CROWN MOLDING LAYING MOLDING FLAT ON THE MITER TABLE Your compound miter saw does an excellent job of See Figure 32. cutting crown molding. In general, compound miter saws do a better job of cutting crown molding than To use this method for accurately cutting crown any other tool made.

- Page 26 OPERATION When cutting crown molding by this method the bevel angle should be set at 33.85°. The miter angle should be set at 31.62° either right or left, depending on the desired cut for the application. See the chart below for correct angle settings and correct positioning of crown molding on miter table.

-

Page 27: Maintenance

WARNING: EXTENSION CORDS When servicing, use only identical Craftsman replacement parts. Use of any other The use of any extension cord will cause some loss of part may create a hazard or cause product power. To keep the loss to a minimum and to prevent damage. -

Page 28: Maintenance

MAINTENANCE WARNING: To ensure safety and reliability, all Your saw has externally accessible brush assemblies repairs — with the exception of the externally that should be periodically checked for wear. accessible brushes — should be performed by a Proceed as follows when replacement is required: qualified service technician at a Sears store to Unplug your saw. - Page 29 NOTES...

-

Page 30: Exploded View And Repair Parts List

CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 Figure A... - Page 31 CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your COMPOUND MITER SAW or when ordering repair parts.

- Page 32 CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 Figure B...

- Page 33 CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your COMPOUND MITER SAW or when ordering repair parts.

- Page 34 CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 SEE NOTE “A” Figure C...

- Page 35 CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212120 The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your COMPOUND MITER SAW or when ordering repair parts.

-

Page 36: Parts Ordering / Service

In U.S.A. or Canada for in-home major brand repair service: Call 24 hours a day, 7 days a week 1-800-4-MY-HOME (1-800-469-4663) Para pedir servicio de reparación a domicilio – 1-800-676-5811 Au Canada pour tout le service ou les pièces – 1-800-469 4663 For the repair or replacement parts you need: Call 6 a.m.