ABB ACS880 - Drives Manual

- Firmware manual (764 pages) ,

- Manual (646 pages) ,

- Quick start up manual (146 pages)

Advertisement

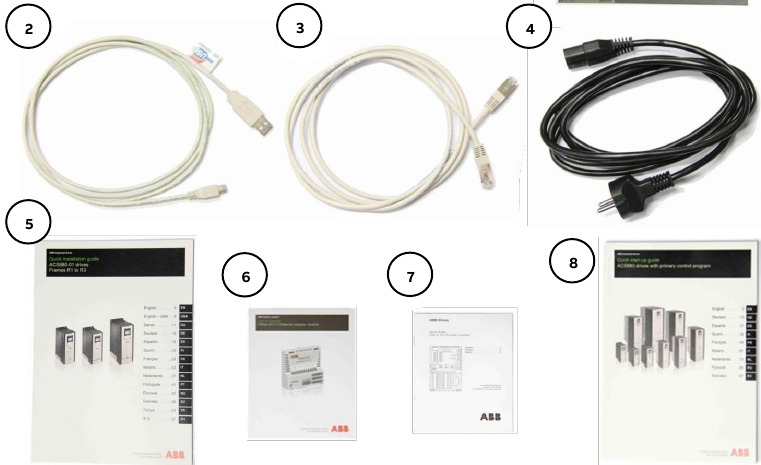

Delivery content

ACS880-01 democase contains: (found in the pocket at the back of the democase)

- I/O-panel with removable control panel

- USB to Mini USB –cable for PC-connection

- Ethernet cable for IO-panel connection

- Mains cord

- Quick installation guide ACS880-01 frames R1 to R3

- FENA-01/-11 Ethernet adapter module manual

- FEN-31 HTL encoder interface quick guide

- Quick start-up guide for primary control program

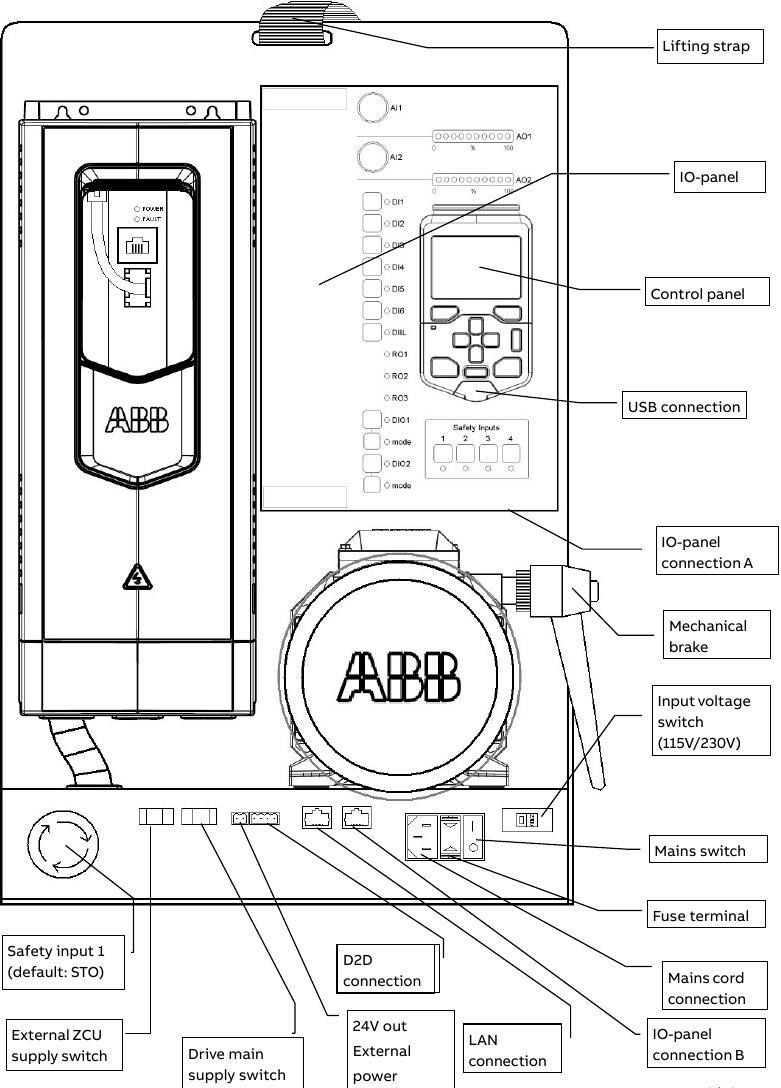

Layout

Supply switches

The demo supply can be controlled with the switches external ZCU supply switch and drive main supply switch. The two switches work separately. The external ZCU supply switch controls the external 24V supply to the control unit of the drive and the drive main supply switch controls the 400V main supply to the drive.

For information about the internal connections refer to Technical data section.

Replacing the fuses

Turn off the democase and disconnect the power cord before changing the fuse. Replace the fuse with the same type of fuse.

Replacing the fuse does not require any tools. Open the fuse terminal by pressing together the pins on the top and bottom of the fuse terminal and pulling the terminal out. Pull out the old fuses and replace them with new fuses of the same type. Push the fuse terminal back in.

Correct fuse type is: T2AL250V (Slow, 2.0A, 250V glass tube fuse) There are two fuses of this type in the fuse terminal.

Basic start-up

- Put the democase on its back (so that the cover is pointing up) and open the cover.

- Pull the demo out of the case using the lifting strap and the handle hole (on the lower part of the demo.)

The demo weighs approximately 18 kg. Use of a proper lifting technique with a straight back. - Take out the mains cord and Ethernet cable from the pocket at the back of the demo.

- Plug in the mains cord and Ethernet cable (to connections marked: mains cord, IO-panel connection A and IO-panel connection B on the layout section.)

- Make sure that the input voltage switch (115V/230V) is set according to the supply voltage. *

- Make sure that the drive main supply is switched on.

- Switch on the demo using the mains switch.

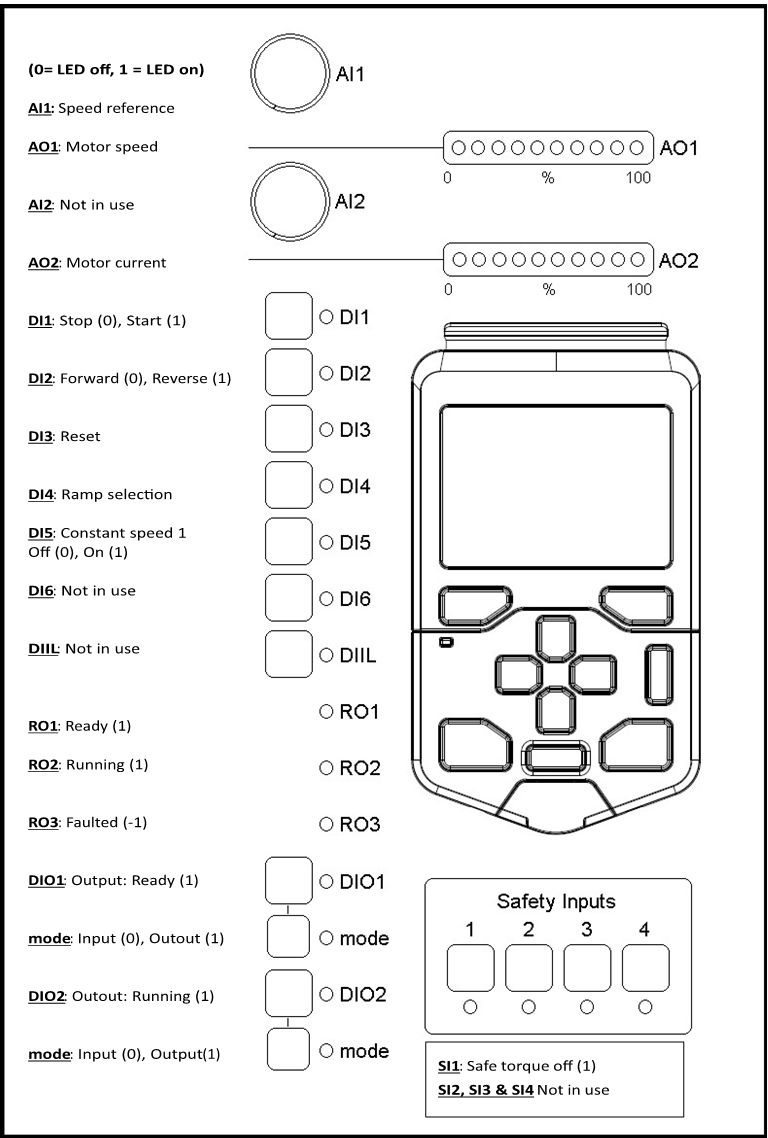

- You can toggle control between the control panel and the IO-panel with the "Loc/Rem" –button on the control panel.

* For more information refer to "AC input (supply) connection" in the Technical data section

Default I/O-panel functions

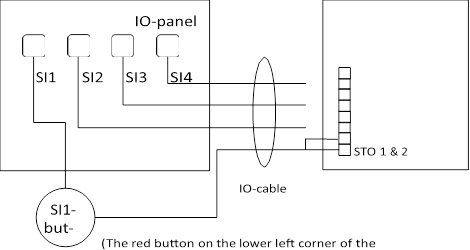

Safety input connections

The safety connections in the demo are made as in the picture below. Safety inputs 2, 3 and 4 are not in use by default. Note that if the IO-cable is not connected, it will automatically result in activation of the STO (safe torque off).

Internal connections

Parameters that need to be changed

| Parameter | Name | Setting | Notes |

| 95 | HW configuration | ||

| 95.01 | Supply voltage | [2] 380...415 V | Correct rating settings made |

| 91 | Encoder module settings | ||

| 91.11 | Module 1 type | [4] FEN-31 | |

| 91.12 | Module 1 location | 003 | FEN-31 location in Option slot 3 |

| 92 | Encoder 1 configuration | ||

| 92.01 | Encoder 1 type | [5] HTL | |

| 92.02 | Encoder 1 source | [1] Module 1 | |

| 92.10 | Pulses/revolution | 1024 | |

| 92.12 | Speed calculation mode | [0] A&B all | |

| 92.13 | Position estimation enable | [0] Disable | |

| 92.15 | Transient filter | [2] 1220 Hz | |

| 92.20 | Enc cable fault func | [0] No |

After setting feedback parameters, activate settings with

| 91 | Encoder 1 configuration | ||

| 91.10 | Encoder parameter refresh | [1] Configure | Will return to 'Done' after refresh |

| 90 | Feedback selection | ||

| 90.41 | Motor feedback selection | [1] Encoder 1 |

I/O settings

| 12 | Standard AI | |

| 12.25 | AI2 unit selection | [2] V |

| 12.28 | AI2 max | 10 |

Motor parameters and ID-run

| 99 | Motor data | ||

| 99.03 | Motor type | [0] Asynchronous motor | |

| 99.04 | Motor ctrl mode | [0] DTC | |

| 99.06 | Motor nominal current | 1.2 A | |

| 99.07 | Motor nominal voltage | 230 V | |

| 99.08 | Motor nominal frequency | 50 Hz | |

| 99.09 | Motor nominal speed | 1360 rpm | |

| 99.10 | Motor nominal power | 0.18 kW | |

| 99.11 | Motor nominal cosfii | 0.71 | |

| 99.13 | Identification run request | [1] Normal | Start ID-run in 'Remote' Press DI1, in 'Local': Press panel Start button |

Technical data

Dimensions of the democase

Height: 650 mm / 26.5 in

980 mm / 38.6 in (trolley handle pulled up)

Width: 490 mm / 19.3 in

Depth: 385 mm /15.2 in

Weight: 27 kg / 60 lb

Drive type code

ACS880-01-02A4-3+K473+L502

(K473 = FENA-11, L502 = FEN-31)

Motor details

Motor type code:

ABB M2VA 63 B 4 (3GVA 062 142-ASC)

Motor nameplate:

| Parameter | ACS880-01 parameter | Value |

| Motor type | 99.03 Motor type | AM |

| Rated current In | 99.06 Motor nominal current | 1.2 A |

| Rated voltage Un | 99.07 Motor nominal voltage | 230.0 V |

| Frequency Fn | 99.08 Motor nominal frequency | 50.0 Hz |

| Rated speed | 99.09 Motor nominal speed | 1360 rpm |

| Rated power Pn | 99.10 Motor nominal power | 0.18 kW |

| COS <p | 99.11 Motor nominal cosfii | 0.71 |

| Rated torque | 99.12 Motor nominal torque | 0.82 Nm |

AC input (supply) connection

U1 ~ 100V - 240V

The democase can be used with both 115V and 230V supply. It is important to make sure that the input voltage switch (115V/230V) is in the correct position for the supply. For example if you are using 230V supply, then "230V" should be visible in the switch. If the switch is set incorrectly you will burn the fuse.

Degree of protection

Drive: IP21

Motor: IP55

Ambient conditions

The demo is designed for demonstration purposes and for indoor use only.

Ambient temperature:

- Transport: -40 to +70°C

- Storage: -40 to +70°C

- Operation: -15 to +40°C, no frost allowed

Altitude:

- 0 to 4,000 m without an effect on demo operation

Relative humidity:

- 5 to 95%, no condensation allowed

For more detailed information, refer to the drive Hardware Manual.

Further information

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting the type designation and serial number of the unit in question. A listing of ABB sales, support and service contacts can be found by navigating to www.abb.com/searchchannels.

Product training

For information on ABB product training, navigate to new.abb.com/service/training.

Providing feedback on ABB manuals

Your comments on our manuals are welcome. Navigate to new.abb.com/drives/manuals-feedback-form.

Document library on the Internet

You can find manuals and other product documents in PDF format on the internet at www.abb.com/drives/documents.

Safety instructions

General safety instructions

These safety instructions are intended for all personnel who work on the drive. For complete safety instructions, see the drive hardware manuals.

Obey these instructions. If you ignore them, injury or death, or damage to the equipment can occur. If you are not a qualified electrical professional, do not do installation or maintenance work.

- Make sure that the drive and all adjoining equipment are properly grounded.

- Do not do any maintenance on powered drive.

- After disconnecting the input power, always wait for 5 minutes to let the intermediate circuit capacitors discharge before you start working on the drive, motor or motor cable.

- Measure that the installation is de-energized. Use a quality voltage tester. Before and after you measure the installation, verify the operation of the voltage tester on a known voltage source.

If the demo unit is operated within the transportation enclosure, note that the motors and drives have less air available for cooling, which may result in overheating.

The democase is intended for demo purposes only. Using democase as a part of any process or application other than the intended demo use is strictly prohibited. Never remove the cover of the motor shaft or connect a load to it.

The democase (demo drive inside transportation case) is a heavy item, see the weights in the Technical data section. Follow the lifting instructions found inside the democase. Lifting the democase requires two persons. Do not lift the democase alone!

General guidelines for safe lifting

- Get as close to the load as possible.

- Keep your elbows and arms close to your body.

- Keep your back straight during the lift by tightening the stomach muscles, bending at the knees, keeping the load close and centered in front of you, and looking up and ahead.

- Get a good grip and do not twist while lifting.

- Do not jerk; use a smooth motion while lifting.

- If the load is too heavy to allow this, find someone to help you with the lift.

- Do not lift more than 25 kg or 50 pounds.

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Thank you! Your question has been received!

Need Assistance?

Do you have a question about the ACS880 that isn't answered in the manual? Leave your question here.