Summary of Contents for GE E2 Series

- Page 1 OSMONICS E2/EZ2 SERIES WATER PURIFICATION MACHINES INSTALLATION, OPERATION, AND MAINTENANCE MANUAL GE Infrastructure Water & Process Technologies...

- Page 2 Distributor Information Distributor: Contact: Phone: Fax: Email: Machine Information Installation Date: Model Number: Serial Number: Service Assistance Consult the Troubleshooting Section of this manual (Section 2.19). If the problem cannot be identified and correct- ed, contact your distributor. Prior to making the call, have the following information available: Model Number Serial Number...

-

Page 3: Table Of Contents

WATER PURIFICATION MACHINES INSTALLATION Mounting the Unit Plumbing Plumbing Connections Feed Water Requirements Transporting Pure Water (Permeate) to Point-of-Use Machine Control 2.6.1 Economy Model 2.6.2 Deluxe Model Single-Phase Electrical Machine Start-Up Preparations 2.8.1 Pretreatment for Water Purification 2.8.2 Machine Start-Up Preparation Machine Start-Up 2.10 Recovery... - Page 4 E2/EZ2-Series Machine Piping Connections E2/EZ2-Series Feed Water Requirements E2/EZ2-Series Primary Pressure Range Flow Specifications for E2/EZ2-Series Machines Permeate Back Pressure Correction Factors NOTE: This manual, along with all GE Infrastructure manuals, is available at www.ge.water.com. LIST OF FIGURES LIST OF TABLES Page...

-

Page 5: Installation

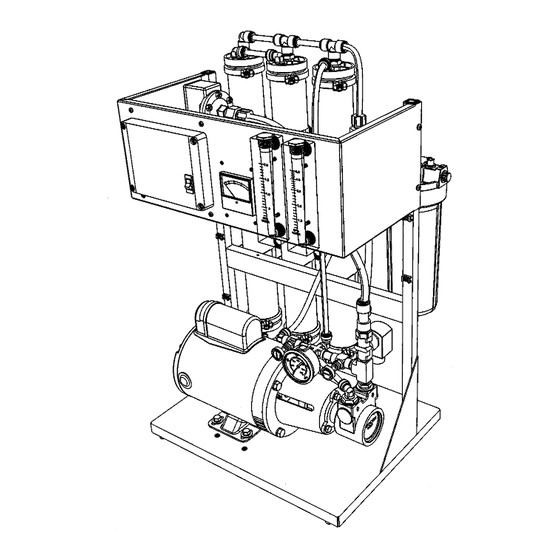

INSTALLATION Mounting the Unit When installing your new GE Osmonics reverse osmosis (RO) machine, allow at least 45-inches (114.3 cm) above the machine for membrane element removal and loading. If space is not available, the entire membrane element housing can be removed for membrane element change-outs. -

Page 6: Feed Water Requirements

Feed Water Requirements The following feed water requirements must be met before installing your E2/EZ2-Series machine to ensure quality permeate and extended membrane element life. Refer to E2/EZ2- Table 2.2 ( Series Feed Water Requirements) for feed water information. Temperature Inlet Pressure Chlorine (continuous feed) -

Page 7: Machine Control

Machine Control 2.6.1 Economy Model To remotely control the Economy Model (ECN) with float switches and/or pre- treatment lockout, remove the jumper between terminals 4 and 5 and wire in the float switches or pretreatment components in series. After all field wiring is com- plete and complies with local and national electrical codes, move onto Section 2.7 (Single-Phase Electrical). -

Page 8: Machine Start-Up Preparation

Your RO is designed to operate on softened tap feed water with an SDI of 5 or less. The pH should be in a range of 5.5 - 8.5. Exposure to any levels of chlo- rine may cause irreversible damage to the Thin-layer composite (TLC) polyamide (PA) membrane elements in your machine. -

Page 9: E2/Ez2-Series Primary Pressure Range

Turn the ON/OFF button on the machine ON. As the pump starts to build pressure, begin to adjust the valves in the following manner: start by slowly closing the concentrate valves while slowly opening the recycle valve (Figure 2.1, Flow Control Center). CAUTION: Monitor machine to ensure inlet pressure of 30 - 60 psi (2.1 - 4.1 bar) is maintained during operation. -

Page 10: Flow Control Center

Complete the Start-Up Data Sheet (Technote 101). The Start-Up Data Sheet and the Daily Log Sheet (Technote 106) are invaluable in diagnosing the performance of the equipment, and must be be kept for reference. If you have questions con- cerning the operation of your machine or the method of data recording, contact your distributor or the manufacturer. -

Page 11: Recovery

2.10 Recovery The machine flow specifications listed below are based on 77°F (25°C). E2/EZ2-Series Units 0375 Recovery Range 33 - 50% Rejection Rate 95 - 98% Permeate Rate 0.3 (0.07) gpm (m Concentrate Rate 0.3 - 0.2 gpm (m (0.07 -0.14) Table 2.4 E2/EZ2 - Series Flow Specifications for... -

Page 12: Permeate Back Pressure Correction Factors

2.11 Permeate Back Pressure Correction Factors It is often necessary to operate RO machines with permeate back pressure. Permeate back pressure will decrease permeate production. See Table 2.5 (Permeate Back Pressure Correction Factors) to calculate loss of permeate. BACK PRESSURE 10 psig (0.7 barg) 20 psig (1.4 barg) 30 psig (2.0 barg) -

Page 13: Operation And Maintenance

A pressure drop across the filter of 8 psi (0.55 bar) or more during operation indicates that the pre-filter cartridge(s) need changeing. Use only GE approved filters rated at 2 microns or less. Refer to Technote 109 (Spare Parts List) for pre-filter cartridge replacements. Do not attempt to clean used pre-filter cartridges. -

Page 14: Membrane Element Cleaning

The permeate quality begins to decline. The reading on the final pressure gauge begins to change noticeably. GE recommends that you clean your E2/EZ2-Series RO machine every quarter. You may have to clean the RO machine more frequently, depending on the quality of your feed water. -

Page 15: Closed Loop Membrane Element Cleaning

Figure 2.2 E2/EZ2-Series Closed Loop Membrane Element Cleaning NOTE: This clean container will be referred to as the Clean-In-Place (CIP) container. Disconnect and route the inlet, permeate, concentrate lines from their service locations to the CIP container (Figure 2.2 E2/EZ2-Series Closed Loop Membrane Element Cleaning. -

Page 16: Membrane Element Removal

After circulaiting the macine for 10 - 15 minutes or solution has reached 95°F (35°C), shut machine OFF. Dump solution. Repeat Setps 6 - 8. With machine OFF (Step 8), let cleaning solution dwell in machine for 15 - 30 minutes. After 15 - 30 minutes, reconnect feed to RO unit and connect concentrate and per- meate to drain. -

Page 17: Membrane Element Installation

element housing. As you reach the bottom of the housing slowly guide the PVC stem or stinger on the end of the membrane element into the head of the end cap. As the membrane element slides into the housing the brine seal will be on the top (Figure 2.4, Direction of Membrane Element Installation). -

Page 18: Membrane Element Direction For Installation

Figure 2.4 Membrane Element Direction for Installation... -

Page 19: Troubleshooting

The operator can easily correct may of these problems, however, for those that persist or are not understood you should contact the GE Customer Support Center. Have the following information available when calling the Customer Support Center:... - Page 20 T R O U B L E S H O O T I N G G U I D E PROBLEM Low operating pressure Concentrate or recycle valve to (continued) Low permeate production Brine seal has “rolled” or been POSSIBLE CAUSES far open Low operating pressure Machine operating on cold...

- Page 21 T R O U B L E S H O O T I N G G U I D E PROBLEM Low permeate production (continued) Inaccurate permeate flow meter Low concentrate flow with normal or high operating pressure Declining rejection (high permeate conductivity) ON/OFF switch ON:...

- Page 22 T R O U B L E S H O O T I N G G U I D E PROBLEM ON/OFF switch ON: machine not running (continued) Pressure does not drop when concentrate valve opened Excessive pressure drop acrosse membrane element(s) [over 50 psi (3.5 bar)] POSSIBLE CAUSES...

- Page 23 T R O U B L E S H O O T I N G G U I D E PROBLEM POSSIBLE CAUSES REMEDIES Flow through machine while Inlet solenoid valve not fully Ensure valve is not getting any power is OFF closed power when machine is OFF.

- Page 25 For more information call 952-933-2277 or 800-848-1750 in the U.S., or visit www.gewater.com. GE Infrastructure Water & Process Technologies North American Sales Euro/Africa Sales 5951 Clearwater Drive 230 rue Robert Schurman Minnetonka, MN ZA des Uselles 55343-8995 77350 Le Mée sur Seine...