Summary of Contents for HP Refrigerated Recirculating Chillers

- Page 1 Operators Manual Refrigerated Recirculating Chillers Powerful Cooling Microprocessor Controller Digital Set & Read with High Flow Centrifugal Pump, Positive Displacement Pump or Turbine Pump 110-116 rev. D ecn 1390...

-

Page 2: Table Of Contents

Table of Contents Section 1 - General Information Warranty Unpacking Package Contents Description Specifications and Pump Performance Section 2 - Set Up Location Reservoir Fluids Pump, Hoses and Couplings Setting Up a Closed System or Cooling Coil to the Chiller Setting Up an Open Bath System to the Chiller Section 3 - Operation Power Requirements... -

Page 3: Section 1 - General Information

Section 1 - General Information 1.1 Warranty Thank you for your purchase. We are confident it will serve you for a long time. Our warranty to you is as follows: The manufacturer agrees to correct for the original user of this product, either by repair, or at the manufacturer’s election, by replacement, any defect which develops after delivery of this product within the period as stated on the warranty card. -

Page 4: Specifications And Pump Performance

Centrifugal Pump Capacity General Specifications To All Chillers Temperature Setability ± 0.1°C Temperature Uniformity ± 0.5°C Readout Selectability °C or °F Pump Inlet & Outlet 2 inch NPT Pump Performance Positive Displacement Pump Capacity Comparison of Pump Options 1 HP... - Page 5 6000 Series Standard Chillers with Magnetic Drive Centrifugal Pump Model 6205 Operating Temperature -5° to 40°C Compressor 4 hp Cooling Capacity @ 20°C 750 Watts 10°C 450 Watts 0°C 100 Watts Pressure at 0 Flow Rate 10 psi Flow Rate @ 0 psi 4.3 gpm / 16.3 lpm...

- Page 6 6000 Series Standard Chillers with Magnetic Drive Centrifugal Pump Model 6705 Operating Temperature -15° to 40°C Compressor 4 hp Cooling Capacity @20°C 2500 Watts @10°C 1700 Watts @ 0°C Pressure at 0 Flow Rate 10 psi Flow Rate @ 0 psi 4.3 gpm / 16.3 lpm...

-

Page 7: Section 2 - Set Up

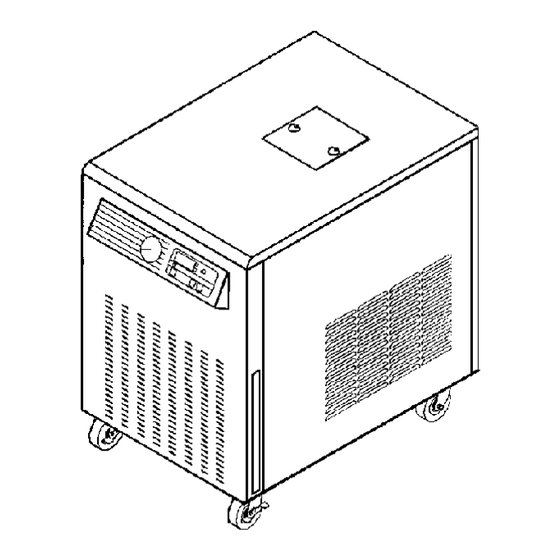

Section 2 - Set Up 2.1 Location Locate the chiller on a strong, level surface. Insure easy access to the top cover and position the chiller for unobstructed air flow through the front and rear screens. The front wheels can be locked to keep the chiller in place while in use. -

Page 8: Setting Up A Closed System Or Cooling Coil To The Chiller

IMPORTANT! Chillers equipped with a high pressure positive displacement pump have a pressure regulator inside of the chiller and a pressure gauge on the control panel. To access this regulator, remove the rear air grille. The valve is located to the right. On models 6107 & 6705, 6155 the regulator is located center point, upper grille (rear). -

Page 9: Section 3 - Operation

Section 3 - Operation 3.1 Power Requirements Caution! Be sure that the power supply is the same voltage as specified on the nameplate With the chiller plugged in (before pressing the P standby (...). If there is no response, check that the circuit breaker on the rear of the chiller is in the ON position. -

Page 10: Setting The Readout High Limit

3.4 Setting the Readout High Limit This feature limits the readout setability so the operating temperature setting cannot easily be set above the High Limit you select. It is not an over temperature feature which shuts off the chiller. To set the readout High Limit: Press and hold the Set/Menu button until the display reads “UNITS”. -

Page 11: Section 4 - Diagram Of Models

6705 & 6105 6205 & 6305 & 6505 OVER CCESS ESERVOIR CCESS ANEL EMPERATURE ROBE RESSURE EGULATOR NLET Fluid In UTLET Fluid Out RAIN ILTER EMPERATURE ROBE CCESS EMALE ONNECTOR IRCUIT REAKER IEC 320 ONNECTOR OLTAGE RAIN RAIN ILTER ROVISION FOR EMALE ESERVOIR ONNECTOR... - Page 12 6155...

-

Page 13: Section 5 - Maintenance

Section 5 - Maintenance Prepare a schedule to perform these specific maintenance tasks at their recommended intervals. 5.1 Standard Magnetic Drive Centrifugal Pump Motor When the chiller is used continuously, this pump motor must be oiled every 6 months with SAE 20 oil. Press the P OWER oil ports located on the pump motor.