Table of Contents

Advertisement

Available languages

Available languages

Quick Links

BEFORE INSTALLATION

The LP916A, B and C Pneumatic Remote Bulb Thermostats

provide proportional control of heating or cooling in induction

units, fan coil units and unit ventilators. A wide throttling range

model is available for duct discharge control of heating or

cooling coils and mixed air dampers.

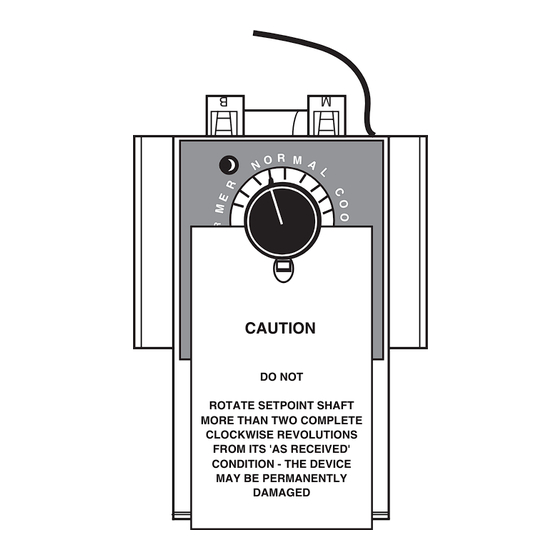

CAUTION

Equipment Damage Hazard.

Do not rotate the thermostat control shaft more than

two revolutions clockwise from the original position as

received. Rotating the shaft more than two revolutions

from the original position can cause permanent

damage to the thermostat.

The caution is also on a removable tag attached to the

thermostat and should remain attached until the system is

ready to start up. See Fig. 1.

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

LP916A, B and C Pneumatic

Remote Bulb Thermostats

Fig. 1. The LP916 caution label removable tag.

Use care to prevent the capillary and sensing bulb from being

dented or damaged during installation. Avoid any sharp bends

or kinks in the capillary.

INSTALLATION INSTRUCTIONS

CAUTION

DO NOT

ROTATE SETPOINT SHAFT

MORE THAN TWO COMPLETE

CLOCKWISE REVOLUTIONS

FROM ITS 'AS RECEIVED'

CONDITION - THE DEVICE

MAY BE PERMANENTLY

DAMAGED

C4646

95-5559EF

Advertisement

Table of Contents

Summary of Contents for Honeywell LP916A

- Page 1 Remote Bulb Thermostats INSTALLATION INSTRUCTIONS BEFORE INSTALLATION The LP916A, B and C Pneumatic Remote Bulb Thermostats provide proportional control of heating or cooling in induction units, fan coil units and unit ventilators. A wide throttling range model is available for duct discharge control of heating or cooling coils and mixed air dampers.

-

Page 2: Installation

INSTALLATION Integral Mounting Bracket Model 2. Mount the thermostat in the location where the mount- ing screws are readily accessible and the setpoint knob The LP916 integral mounting bracket model includes two easily reached. Preferably the scale is visible from the Tinnerman nuts, two sensing bulb hangers and two No. -

Page 3: Duct Mounting

NOTE: When air connections are towards the back, connect the appropriate lengths of tubing to the barb connec- tors before mounting. Duct Mounting Duct mounting requires a 107324A duct bulb holder. See Fig. 7. The sensing bulb should be located in the duct where air of representative temperature can freely circulate. -

Page 4: Panel Mounting

CAPILLARY 4-7/8 (124) 4-1/2 (115) BE SURE THIS TUBE IS UNDER 2-3/16 (56) 2-1/16 (53) BULB HOLDER, AS SHOWN M18343 C4653 Fig. 9. Mounting the capillary tubing in the bulb holder. 6. Insert the bulb and bulb holder into the duct through the Fig. -

Page 5: Bracket Mounting

CAPILLARY MAIN BRANCH 3-1/4 PROTECTED BARBS (83) THERMOSTAT CONTROL SHAFT SCALEPLATE 10-32 x 1/4-IN. SCREW (2) (16) 1-7/8 (48) 2-3/4 (70) C4648 SETPOINT KNOB Fig. 15. Mounting bracket in 316016A bag assembly. Dimensions are in in. (mm). SENSING BULB C4652 Fig. - Page 6 ���������������������������������������������������������������������� ��������������������������������������������������� APPLICATIONS Refer to Figs. 18 through 21 for typical applications. DAMPER OPERATOR N.O. DISCHARGE N.O. N.C. LP916A M5449 LP916A DISCHARGE Fig. 19. Typical LP916A mixed air application. SUPPLY M5417 Fig. 18. Typical LP916A duct mounted heating application. 95-5559EF...

-

Page 7: Checkout And Testing

If recalibration is required, always allow enough time (up to three minutes) for the branch pressure to stabilize. LP916A and C Calibration FILTER 1. Apply 18 psi (124 kPa) main line pressure. 2. Measure the temperature at the bulb location. -

Page 8: Lp916B Calibration

1. Back off the switchover spring adjusting nut until flush CAUTION with the stud. See Fig. 22. 2. Calibrate per Steps 1 through 5 of the LP916A and C Equipment Damage Hazard. Calibration section. Increase the branchline pressure by Rotating shaft more than two revolutions rotating the control shaft clockwise. -

Page 9: Notice D'installation

à distance LP916A, B et C NOTICE D’INSTALLATION AVANT D'INSTALLER CE PRODUIT… Les thermostats pneumatiques à bulbe à distance LP916A, B et C assurent la régulation proportionnelle du chauffage ou du refroidissement dans les éjecto-convecteurs, les ventilo- convecteurs et les ventilateurs. Un modèle à large bande proportionnelle est offert pour la régulation des serpentins de... -

Page 10: Modèle À Support De Montage Intégré

THERMOSTATS PNEUMATIQUES Ω BULBE Ω DISTANCE LP916A, B ET C INSTALLATION 4. Monter le bulbe dans l'un ou l'autre des compartimants E. Voir la Fig. 3. Prendre garde de plier à angle aigu, de tortiller ou de pincer le tube capillaire de 914 mm (36 po). - Page 11 THERMOSTATS PNEUMATIQUES Ω BULBE Ω DISTANCE LP916A, B ET C 4. Passer le bulbe et le tube capillaire dans l'ouverture de l«ouverture défonçable. Placer le bulbe entre le filtre de reprise d'air et le serpentin. Poser une garniture d'étanchéité dans la paroi de l'unité pour protéger le tube capillaire.

-

Page 12: Modèle Avec Trousse De Montage

THERMOSTATS PNEUMATIQUES Ω BULBE Ω DISTANCE LP916A, B ET C Modèle avec trousse de montage Le modèle avec trousse de montage LP916 est illustré à la TUBE CAPILLAIRE Fig. 12. Ce modèle peut être monté sur un panneau ou dans une unité... -

Page 13: Montage Sur Support

THERMOSTATS PNEUMATIQUES Ω BULBE Ω DISTANCE LP916A, B ET C TUBE CAPILLAIRE CANALISATION PRINCIPALE CANALISATION SECONDAIRE CANNELURES PROTÉGÉES (3-1/4) THERMOSTAT ARBRE DE COMMANDE PLAQUE GRADUÉE (5/8) 48 (1-7/8) 70 (2-3/4) CF4648 VIS 10-32 x 1/4 PO(2) Fig. 15. Support de montage de l'ensemble 316016A. - Page 14 THERMOSTATS PNEUMATIQUES Ω BULBE Ω DISTANCE LP916A, B ET C 4. Tenir le thermostat à l'endroit où il sera posé et marquer REMARQUE : Pour une installation avec des rivets à tôle, le centre des trous de vis dans l'unité terminale. Voir la faire des trous de passage pour les vis.

-

Page 15: Vérification Et Essais

THERMOSTATS PNEUMATIQUES Ω BULBE Ω DISTANCE LP916A, B ET C VÉRIFICATION ET ESSAIS SORTIE D'AIR AVERTISSEMENT LP916B ÉTÉ/HIVER Risque de dommage du matériel Ne pas faire faire à l'arbre de commande du thermostat plus deux tours, dans le sens horaire, par SERPENTIN rapport à... -

Page 16: Étalonnage Du Lp916B

(jusqu'à trois minutes). By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including attorneys’...