Advertisement

Quick Links

installation and

servicing

istor

Your Ideal installation and servicing guide

For details of document amendments, refer to page 3

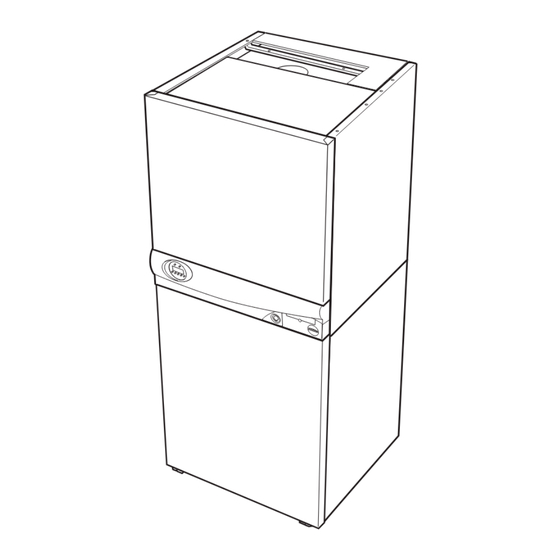

HE260 & HE325

For user guide see reverse of book

When replacing any part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require. Do not

use reconditioned or copy parts that have not been clearly authorised by Ideal Boilers.

July 2005

UIN 159 979 A07

For the very latest copy of literature for specification purposes please visit our website

www.idealboilers.com where you will be able to download the relevant information in pdf format.

ENGINEERED FOR PEACE OF MIND

Advertisement

Summary of Contents for Ideal Boilers Istor HE260

- Page 1 When replacing any part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by Ideal Boilers. July 2005...

- Page 2 istor system store - Installation and Servicing...

- Page 3 DOCUMENT AMENDMENTS Relevant Installation changes implemented in this book from Mod Level .....A06 (Mar 05) to A07 (Jul 05) • Page 32, Frame 40 - Pictorial Wiring Diagram New wiring changes. • Page 51, Frame 81 - Boiler Automatic Air Vent Replacement Spacer removed and new plug supplied.

- Page 4 GENERAL Table 1 - General Data Boiler size istor HE260 istor HE325 Gas supply 2H - G20 - 20mbar Gas Supply Connection Rc 1/2 (1/2” BSP female) Injector size Stereomatic 5.6mm dia. Inlet Connection Domestic Hot Water 22mm copper Outlet Connection...

-

Page 5: Table Of Contents

GENERAL istor CONTENTS Air Supply ............... 9 Natural Gas only Benchmark Commissioning Checklist ..... 68 Boiler size G.C. Appliance No. PI No. Boiler Clearances ............8 (Benchmark No.) Boiler Exploded Diagram ......... 15,16,17 HE260 41-394-13 0063 BM 3094 Condensate Drain ............11 HE325 41-394-14 0063 BM 3094... -

Page 6: Safe Handling

GENERAL INTRODUCTION 1 BOILER WATER CIRCUIT DIAGRAMS The istor HE260 & HE325 boilers are a fully automatically controlled, Central Heating Circuit condensing, system store, fanned flue, gas boiler. Note. Due to the high efficiency of the boiler a plume of water vapour will form at the terminal during operation. - Page 7 GENERAL OPTIONAL EXTRA KITS IMPORTANT. These appliances are CE certificated for safety and performance. It is, therefore, important that no external ! Flue Kits (for more details see pages 10 & 11). control devices, e.g. flue dampers, economisers etc., are directly connected to these appliances unless covered by these ! Condensate pump Kit.

- Page 8 GENERAL BOILER DIMENSIONS, SERVICES & CLEARANCES all dimensions in mm (in) The boiler connections are made on the boiler piping frame. Refer to Frame 22. Installation from inside ONLY b. If a core boring tool is to be used inside the building The following minimum clearances must be maintained for the space in which the boiler is to be installed must operation and servicing.

-

Page 9: Gas Supply

GENERAL GAS SUPPLY 3. Minimum acceptable spacing from the terminal to obstructions and ventilation openings are specified in The local gas supplier should be consulted, at the installation Table 4. planning stage, in order to establish the availability of an adequate supply of gas. - Page 10 GENERAL FLUING OPTIONS istor system store - Installation and Servicing...

-

Page 11: Fluing Options

GENERAL FLUING OPTIONS Twin fluing kit. 80/80 kit to a maximum of 46m combined flue and air duct. 60/60 kit to a maximum of 20m combined flue and air duct (horizontal applications only). THERMOSTATIC RADIATOR VALVES (TRV) ELECTRICAL SUPPLY Caradon Ideal Limited recommend that heating systems WARNING. - Page 12 GENERAL SYSTEM REQUIREMENTS - Central Heating Notes a. The method of filling, refilling, topping up or flushing sealed primary hot water circuits from the mains via a temporary hose connection is only allowed if acceptable to the local water authority. Safety valve setting b.

- Page 13 GENERAL SYSTEM REQUIREMENTS - Domestic Hot Water Domestic Hot Water Requirements (see note in Frame 15). discharged from safety devices is safely conveyed to where it is visible but will not cause danger to persons in or about 1. The domestic hot water service must be in accordance with BS 5546 and BS 6700.

- Page 14 GENERAL SYSTEM REQUIREMENTS - Domestic Hot Water (continued) the installation of an electronically operated device to ! The discharge pipe MUST NOT be blocked or used for warn when discharge takes place. any other purpose. Note. ! The tundish must not be removed. The discharge will consist of scalding water and steam.

-

Page 15: Water Treatment

GENERAL SYSTEM BALANCING BALANCING These valves should now be left as set. 2. Open all manual or thermostatic radiator valves and 1. Set the programmer to ON. adjust the lockshield valves on the remaining radiators, Close the manual or thermostatic valves on all radiators, to give around 15 C temperature drop at each radiator. - Page 16 INSTALLATION 11 BOILER MODULE ASSEMBLY - Exploded View Data badge istor system store - Installation and Servicing...

- Page 17 INSTALLATION 12 TANK MODULE ASSEMBLY - Exploded View istor system store - Installation and Servicing...

- Page 18 INSTALLATION 13 BOILER PACKAGING AND REMOVAL Hardware Pack Mains connector assembly - 1 off. The boiler is supplied in two separate cartons. The tank module carton includes the pre-piping frame, the hardware pack, the floor CH pressure relief pipe - 1 off. template and the Installation &...

- Page 19 INSTALLATION 14 FITTING THE PRE-PIPING FRAME 1. Using the floor template mark the position of the appliance and the fixing holes for the pre-piping frame. 2. Fasten the pre-piping frame to the floor. Using suitable fixing screws and plugs dependant on the floor material, fasten the pre-piping frame to the floor.

-

Page 20: Gas Connection

INSTALLATION 16 CH WATER CONNECTIONS Central Heating connections Refer to the Note in Frame 14 for guidance. IMPORTANT Do not subject any of the isolating valves to heat as the seals may be damaged. 17 GAS CONNECTION Fibre washer IMPORTANT. The gas service cock is sealed with a non-metallic fibre washer so must not be overheated when making capillary... - Page 21 INSTALLATION 18 SAFETY VALVE DRAIN (DHW) The discharge pipe should be positioned so that the discharge of water or steam cannot create a hazard to the occupants of the premises or damage the electrical components and wiring. IMPORTANT. The discharge pipe arrangement must comply with G3 Building Regulations.

- Page 22 INSTALLATION 20 CONDENSATE DRAIN The condensate drain connection point position is shown in when the pipe is run externally the pipe should be run as far the diagram below. A 700mm long flexible hose and adaptor as possible within the building. is provided in the hardware pack for connection to this.

- Page 23 INSTALLATION TANK CONNECTION TO THE PIPING FRAME General Before moving the appliance onto the piping frame provision must be made for the condensate drain which may be easier before the boiler is moved into position. Refer to Transit bracket Frame 20. 1.

-

Page 24: Flue System

INSTALLATION 24 BOILER UNIT CONNECTION General The gas pipe is tied to the DHW safety valve drain. It is suggested that all pipes are connected to the pre-piping frame before boiler connections are made. 1. Lift boiler unit onto the tank frame. 2. - Page 25 INSTALLATION 26 DETERMINING THE FLUE LENGTH AND FLUE PACKS REQUIRED For the 100mm concentric flue system Dimension X - Wall thickness. Total Flue length dimension Flue Dimension L - Wall thickness plus boiler spacing. Rear flue LH Side flue RH Side flue Extra packs dim.

- Page 26 INSTALLATION 28 PREPARING THE WALL WARNING. Ensure that, during the cutting operation, masonry falling outside of the building does not cause damage or personal injury. 1. Cut the flue hole (preferably with a 5" core boring tool), ensuring that the hole is square to the wall. Both wall faces immediately around the cut hole should be flat.

- Page 27 INSTALLATION 29 CUTTING THE FLUE - REAR Note. a. If using the extension ducts go to Frame 34. 1. Measure and note wall thickness X - Refer to Frame 26. 2. Add 115mm (4 ") to dimension X and, measuring from the ring, cut the outer tube only.

- Page 28 INSTALLATION 32 TERMINAL WALL PLATE (optional) This plate is supplied in the Flue Finishing Kit (together with one inner and one outer flue seal) it allows neat concealment and full compression of the outer seal (if fitted). Its use is not essential if the flue hole and flue ducts have been accurately cut and the outside wall face is flat.

- Page 29 INSTALLATION 35 FITTING THE KIT 1. Remove the cardboard support aid from the flue and place safely to one side. 2. Fit the inner flue extension duct onto the inner flue duct. 3. Fit the outer flue extension duct onto the outer air duct. 4.

-

Page 30: Electrical Connections

INSTALLATION 37 ELECTRICAL CONNECTIONS Immersion heater Note. WARNING. This appliance MUST be earthed. An immersion heater is supplied fitted to the cylinder and is Boiler water connection intended for use as a back up heat source of DHW. Wiring of A mains supply of 230 V ~ 50 Hz is required. -

Page 31: External Electrical Controls

INSTALLATION 39 EXTERNAL ELECTRICAL CONTROLS Wiring External to the Boiler The fuse rating should be 3A. Wiring external to the boiler MUST be in accordance with the current I.E.E. (BS.7671) Wiring Regulations and any local regulations. For IE reference should be made to the current ETCI rules for electrical installations. - Page 32 INSTALLATION 40 PICTORIAL WIRING DIAGRAM LEGEND - blue. bk - black. br - brown. - red. Overheat thermostat - yellow. Dry fire - white. thermistor y/g - yellow/ green. Return Flow Diverter valve thermistor thermistor gy - grey. or - orange. Gas valve - violet PUMP...

-

Page 33: Flow Wiring Diagram

INSTALLATION 41 FUNCTIONAL FLOW WIRING DIAGRAM Programmer Mains Switch External switch e.g. PCB No. room'stat. Flame detection electrode Overheat thermostat RAC Gas valve Spark generator electrode Dry fire thermistor DHW thermistor CH return thermistor Pump v v v v CH control thermistor Diverter valve ist8013... -

Page 34: Initial Lighting

INSTALLATION 43 INITIAL LIGHTING Tube LEGEND A. Air vent. B. Inlet pressure test point. C. CH return isolating valve. D. Mains water inlet isolating valve. L. Display. E. Gas service cock. M. Reset button. F . DHW outlet. N. LED. G. - Page 35 INSTALLATION 44 INITIAL LIGHTING - continued 12. Ensure that with the boiler operating the dynamic gas CENTRAL HEATING pressure is able to obtain maximum output. 13. Once the DHW tank is satisfied with the boiler thermostat Refer to Table 2. set to max the diverter valve will move and the boiler will N.B.

-

Page 36: Handing Over

INSTALLATION 46 GENERAL CHECKS - continued WATER CIRCULATION SYSTEM 5. Set the central heating external controls to OFF. The 1. With the system COLD, check that the initial pressure is burner should go off and the pump continue to run for a correct to the system design requirements. -

Page 37: Gas Supply

SERVICING 48 SERVICING SCHEDULE TANK MODULE To ensure the continued safe and efficient operation of the appliance it is recommended that it is checked at regular Note. The unvented DHW cylinder must be inspected and intervals and serviced as necessary. The frequency of serviced annually. - Page 38 SERVICING 51 CONTROLS FACIA PANEL REMOVAL Refer to Frame 50. 1. Ensure the power supply is turned off. 2. Disconnect the 14 way in-line molex connector. 3. Remove the 2 M5 screws securing the panel. 4. Lift off the panel from its locating slots. 5.

- Page 39 SERVICING 53 BOILER SEALING PANEL REMOVAL 1. Turn off the gas supply at the gas service cock and disconnect the electricity supply. 2. Slacken the backnut securing the DHW vessel to its support bracket and remove carefully to one side. It is unnecessary to disconnect the hose at this stage.

-

Page 40: Burner Removal And Cleaning

SERVICING 55 BURNER REMOVAL AND CLEANING 1. Remove the 6 screws securing the burner (the 3 screws at the rear are extended to ease access). 2. Lift off the burner from the combustion chamber. IMPORTANT The burner head is a ceramic plaque construction. -

Page 41: Cleaning The Heat Exchanger

SERVICING 57 CLEANING DHW INLET FILTER 1. Close the DHW inlet isolating valve. 2. Undo the union nut on the isolating valve. Undo the union nut on the inlet side of the water governor. 4. Withdraw the short piece of pipe between the two. -

Page 42: Replacement Of Components

SERVICING 60 REPLACEMENT OF COMPONENTS GENERAL After replacing ANY component check operation of the boiler including gas soundness, gas rate and combustion test. When replacing ANY component in the boiler module. IMPORTANT. 1. Isolate the electricity supply. When work is complete, if the sealing panel has been 2. - Page 43 SERVICING 63 BURNER INJECTOR REPLACEMENT 1. Refer to Frame 50 & 51. 2. Remove the boiler sealing panel. Refer to Frame 53. 3. Disconnect the electrical leads from the fan. 4. Undo the gas pipe union connection to the injector housing. 5.

- Page 44 SERVICING 65 CONTROL THERMISTOR, RETURN THERMISTOR AND OVERHEAT THERMOSTAT REPLACEMENT 1. Refer to Frame 50 & 51. 2. Unclip the thermistor / thermostat from the flow / return pipe and withdraw it from the controls compartment. 3. Disconnect the electrical leads from the thermistor / thermostat.

- Page 45 SERVICING 68 COMBUSTION CHAMBER INSULATION REPLACEMENT 8. Damp down the combustion chamber area containing the The insulation boards used in the combustion chamber of insulation boards. this product are made of high temperature glass fibres with a binder of organic and inorganic materials. 9.

- Page 46 SERVICING 69 GAS CONTROL VALVE REPLACEMENT 1. Refer to Frame 50 & 51. 6. Undo the union nut on the RHS of the gas control valve. 2. Undo the 2 screws securing the control box. 7. Slacken the screw securing the valve mounting bracket and withdraw the valve, complete with bracket and inlet 3.

- Page 47 SERVICING 71 CONDENSATE 'S' TRAP REPLACEMENT 1. Refer to Frame 50 & 51 . 2. Disconnect the condensate drain pipe. 3. Remove the elongated bolts, pull the trap down and forwards to remove. 4. Transfer the drain pipe to the new trap and re-assemble in reverse order.

- Page 48 SERVICING 73 CONTROL BOX REPLACEMENT 1. Refer to Frame 50 & 51 . 2. Remove the fixing screws locating the control box bracket. 3. Unplug all the electrical wiring from the control box and remove. 4. Transfer the fixing bracket to the new control box.

- Page 49 SERVICING 76 DISPLAY UNIT REPLACEMENT Note. Only the display unit is replaced. 1. Refer to Frame 50 & 51. 2. Loosen the screw on the underside of the user control. 3. Pull the display unit forward to remove. 4. Push the new display unit into position.

-

Page 50: Pump

SERVICING 78 SAFETY RELIEF VALVE REPLACEMENT 1. Remove the casing bottom panel. Refer to Frame 50. 2. Drain the boiler. Refer to Frame 3. Remove the discharge pipe. 4. Remove the valve and pressure gauge. 5. Transfer the pressure gauge to the new relief valve. - Page 51 SERVICING 80 TEMPERATURE & PRESSURE RELIEF VALVE REPLACEMENT 1. Refer to Frame 50 & 51. 2. Remove the DHW expansion vessel. Refer to Frame 53. 3. Drain the cylinder. Refer to Frame 83. 4. Remove the control box fixing screws and slide the box to enable the valve to be removed through the cutout in the boiler module base plate.

-

Page 52: Draining The Boiler

SERVICING 82 DRAINING THE BOILER CH Isolating valves 1. Refer to frame 50. 2. Close all the water isolating isolating valve valves on the piping frame. (shown closed) 3. Attach a length of hose to the TO OPEN drain point and open the drain valve. - Page 53 SERVICING 84 DIVERTER VALVE MECHANISM REPLACEMENT 1. Refer to Frame 50 & 51. 2. Drain the boiler. Refer to Frame 82. 3. Undo the 3 union nuts securing the valve body and remove valve. 4. Replace the valve using new fibre washers on the union nuts.

- Page 54 SERVICING 86 CH EXPANSION VESSEL REPLACEMENT 1. Refer to Frame 50 & 51. 2. Drain the boiler. Refer to Frame 82. 3. Undo the union nut on the vessel water connection pipe. 4. Remove the screw and remove the securing clamp. 5.

- Page 55 SERVICING 89 THERMOSTATIC MIXER VALVE REPLACMENT 1. Refer to Frame 50. 2. Drain the cylinder. Refer to Frame 83 3. Undo the 2 union nuts on the mixer valve. 4. Undo the nut on the DHW outlet on the cylinder. 5.

- Page 56 SERVICING 92 HEAT ENGINE REPLACEMENT 15. Using a suitable tool undo the push fit connections from Refer also to Frame 11 - 'Boiler exploded view'. the flow and return pipes of the boiler removing the To replace the heat exchanger it is necessary to separate the pump assembly and the diverter valve assembly.

- Page 57 SERVICING 93 HEAT ENGINE REPLACEMENT - continued interpanel and transfer to the new heat engine. 33. Undo the M5 screw and remove the flow pipe securing bracket. 34. Remove the flow pipe and transfer to the new heat engine. 35. Reassemble in reverse order, replacing gaskets or seals if any sign of damage or deterioration is evident.

-

Page 58: Fault Finding

FAULT FINDING 95 FAULT FINDING CHART MAIN MENU In order to assist fault finding, the boiler has an LED diagnostic display. The key to the display codes is as follows: GO TO FRAME 96 ALTERNATING 'L' 'F' ALTERNATING 'L' 'E' GO TO FRAME 97 ALTERNATING 'L' 'A' GO TO FRAME 98... - Page 59 FAULT FINDING 96 L..F..(FLAME DETECTION) If the boiler reset button is Check gas supply Is 17mbar gas pressure pressed does the boiler ignite and rectify fault available at the boiler inlet ? for a short time then extinguish? Check gas valve Is 200V DC supply Check the detection electrode and wiring for...

- Page 60 FAULT FINDING 100 H..1..(CONTROL TEMPERATURE SENSOR) Check resistance. The sensors can be checked by Remove the boiler control measuring their resistance, using a suitable multimeter thermistor from the CH flow pipe and disconnect connected across the sensors' terminal pins thermistor wires.

- Page 61 FAULT FINDING 103 H..4..(DRY FIRE THERMISTOR) H9/L9 (HEAT EXCHANGER OVERHEAT) Is the system filled and vented and all Can the fault condition be reset by switching off isolation valves open ? the mains supply to the boiler ? Is the pump operating correctly? Ensure flow through system.

-

Page 62: Short List Of Parts

When replacing any part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by Ideal Boilers. - Page 63 SHORT LIST OF PARTS 106 SHORT PARTS LIST ist8016 istor system store - Installation and Servicing...

- Page 64 SHORT LIST OF PARTS 107 BOILER CASING ASSEMBLY 1. Sealing panel with screws. 108 BURNER ASSEMBLY 7. Burner assembly with screws and gasket. Ecl 1598 istor system store - Installation and Servicing...

- Page 65 NOTES istor system store - Installation and Servicing...

- Page 66 NOTES istor system store - Installation and Servicing...

-

Page 67: Installer Notification Guidelines

INSTALLER NOTIFICATION GUIDELINES IT IS A REQUIREMENT OF CORGI MEMBERSHIP TO REGISTER EVERY GAS APPLIANCE In addition a change to Building Regulations (England and Wales) requires the installer to notify when installing a heating appliance, as from 1st April 2005. Install and commission this appliance to manufacturers' instructions... -

Page 68: Thermostatic Radiator Valves

BENCHMARK No. GAS BOILER COMMISSIONING CHECKLIST C O L L E C T I V E M A R K BOILER SERIAL No. NOTIFICATION No. CONTROLS To comply with the Building Regulations, each section must have a tick in one or other of the boxes TIME &... -

Page 69: Service Interval Record

SERVICE INTERVAL RECORD It is recommended that your heating system is serviced regularly and that you complete the appropriate Service Interval Record Below. Service Provider. Before completing the appropriate Service Interval Record below, please ensure you have carried out the service as described in the boiler manufacturer's instructions. - Page 70 & servicing of central heating systems Manufactured under a BS EN ISO 9001: 1994 Quality System accepted by BSI Ideal Boilers, P.O. Box 103, National Ave, Kingston upon Hull, HU5 4JN. Telephone: 01482 492 251 Fax: 01482 448 858. Registration No. London 322 137.

-

Page 72: Important Notes

I n t r o d u c t i o n Electricity Supply (immersion heater) The istor HE260 & HE325 are fully automatically controlled, Supply: 230 V ~ 50 Hz. The fusing should be 13A. condensing, system store, fan flued boilers. -

Page 73: Central Heating

To light the boiler. Control of water temperature Refer to Frame 1 Refer to the programmer section of these instructions to set the Domestic Hot Water required programs. The DHW delivery temperature is controlled by thermostatic 1. CHECK THAT THE ELECTRICITY SUPPLY TO THE BOILER mixer within the tank module (see illustration below). -

Page 74: Frost Protection

To shut down the boiler Loss of system water pressure 1. For short periods The gauge (see illustration below) indicates the central heating system pressure. If the pressure is seen to fall below the Set the mains ON/OFF switch (A) to OFF original installation pressure of 1-2 bar over a period of time 2. - Page 75 PROGRAMMER SET UP Channel 1 (Radiator symbol) relate to the CH programme Channel 2 (Tap symbol) relates to the DHW programme. 1. To set the time and day. Move the right sliding switch to 'RUN'. Press the 'HR' and 'MIN' simultaneously for 2-3 seconds. Set the day button using the 'DAY' button.

- Page 76 The right is therefore reserved to vary specification without notice. Tel: 01482 498660 Ideal Boilers, P.O. Box 103, National Ave, Kingston Upon Hull, HU5 4JN. Tel. www.idealboilers.com 01482 492251 Fax. 01482 448858. Registration No. London 322 137.