Summary of Contents for Canon Color Image Reader-F1

- Page 1 October 10, 2012 Revision 1.1 Color Image Reader-F1 Service Manual Product Outline Technology Periodic Servicing Parts Replacement and Cleaning Procedure Adjustment Installation Appendix...

- Page 2 This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may changes in the contents of this manual over a long or short period, Canon will issue a new not be copied, reproduced or translated into another language, in whole or in part, without the edition of this manual.

- Page 3 Explanation of Symbols The following rules apply throughout this Service Manual: The following symbols are used throughout this Service Manual. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of Symbols Explanation Symbols...

- Page 4 Blank Page...

-

Page 5: Table Of Contents

Contents Product Outline Work of service --------------------------------------------------------------------2-20 Features (Reader) ------------------------------------------------------------1-2 Periodic Servicing Specifications (Reader) ------------------------------------------------------1-2 List of Work for Scheduled Servicing (Reader) ------------------------3-2 Names of Parts (Reader) ---------------------------------------------------1-3 List of Work for Scheduled Servicing (ADF) ----------------------------3-4 External View ----------------------------------------------------------------------- 1-3 Cross Section ----------------------------------------------------------------------- 1-3 Parts Replacement and Cleaning Procedure Features (ADF) ----------------------------------------------------------------1-4... - Page 6 Exchanging the Feed Guide ---------------------------------------------------4-21 Adj of DADF img lead edge margin: front -----------------------------------5-12 Clutch Solenoid Motor Fan PCB (ADF) ------------------------------- 4-22 Fine adj of DADF image magnifictn: front ----------------------------------5-12 Removing the ADF Motor(M1) -------------------------------------------------4-22 White level adj ---------------------------------------------------------------------5-13 Removing the Release Motor(M2) --------------------------------------------4-22 Installation Removing the Pressurization Solenoid(SL1) ------------------------------4-23 Pickup Clutch/Registration Clutch(CL1/CL2) ------------------------------4-23...

-

Page 7: Product Outline

Product Outline ■ Features (Reader) ■ Specifications (Reader) ■ Names of Parts (Reader) ■ Features (ADF) ■ Specifications (ADF) ■ Names of Parts (ADF) Product Outline... - Page 8 Product Outline > Specifications (Reader) Features (Reader) Specifications (Reader) • Low energy consumption by adopting a new Scanner Unit Item Specification/function Remarks • Realization of a compact Scanner Unit by adopting a new lens unit Exposure system High-brightness white LED + reflection plate Original In BOOK Scan by movement of scanner unit...

-

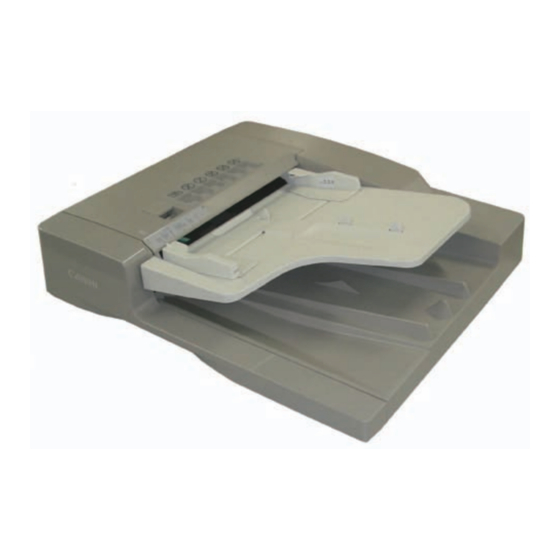

Page 9: External View

Product Outline > Names of Parts (Reader) > Cross Section Names of Parts (Reader) Cross Section Stream Read Glass Copyboard Glass External View Copyboard Glass Glass Retainer (Right) Reader PCB Cover Reader Right Cover Scanner Unit F-1-2 Reader Rear Cover Reader Front Cover Reader Left Cover Glass Retainer (Left) -

Page 10: Features (Adf)

Product Outline > Specifications (ADF) Features (ADF) Specifications (ADF) • Original tray capacity is 100 sheets at maximum. Item Specifications Document pickup method Automatic pickup and delivery • Mixed size loading mode enables the feeder to handle the different width originals in a job. Document loading direction Face-up Document loading position... -

Page 11: Names Of Parts (Adf)

Product Outline > Names of Parts (ADF) > Cross Section Names of Parts (ADF) Cross Section External View [11] [13] Slide guide Feeder Cover Rear Cover Rear Small Cover [12] [15] [14] [10] F-1-4 Lower registration roller Upper registration roller Feed roller Front Cover Separation pad unit... -

Page 12: Technology

Technology ■ Basic Configuration (Reader) ■ Controls ■ Basic Configuration (ADF) ■ Controls (ADF) Technology... -

Page 13: Basic Configuration (Reader)

Technology > Basic Configuration (Reader) > Parts Configuration > Major Electrical Parts Basic Configuration (Reader) Component part Symbol Function/specification Scanner motor 2 phase pulse motor: pulse control Scanner unit exhaust fan Exhaustion of scanner unit Parts Configuration Scanner unit cooling fan Cooling of scanner unit DADF open/closed sensor 1 DADF open detection (DADF is detected at 5 degree) - Page 14 Technology > Basic Configuration (Reader) > Parts Configuration > LED lamp unit ■ Scanner Unit ■ LED lamp unit On LED lamp unit, the light is generated from the 2 LED lamp PCBs (LED chip: 48 pieces Original exposure and scanning are performed by the integrated scanner unit of LED, per PCB).

-

Page 15: Controls (Reader)

Technology > Controls (Reader) > Controls > Detecting the Size of Originals Controls (Reader) ■ Detecting the Size of Originals ● Overview Controls The machine identifies the original size by the combination of measurement result of reflection ■ Enlargement/Reduction light from the reflection sensor and specific points of CCD. Also to identify it accurately even though an original moves when ADF is closed, the machine measures 2 points for each size. - Page 16 Technology > Controls (Reader) > Controls > IDirt Sensor Control ● Control Details ■ IDirt Sensor Control In horizontal scanning direction, sensor level of each original detection position is measured ● Overview by moving the Scanner Unit to the detection position shown in the figure in relation to the When reading an original, original reading position is changed according to the presence/ original set position.

- Page 17 Technology > Controls (Reader) > Controls > IDirt Sensor Control [Particulars of control] • Between sheets • At the end of a job (dust detection) The Scanner Unit does not move. The Reading Sensor detects presence/absence of dust at the reading position A, B, and C It reads the original using the position determined at the end or start of a job;...

-

Page 18: Basic Configuration (Adf)

Technology > Basic Configuration (ADF) > Component Configuration > Roller Layout Basic Configuration (ADF) ■ Roller Layout Component Configuration ■ List of Major Electric Parts [10] [11] ADF driver PCB(PCB1) Pressurization solenoid(SL1) ADF Fan(FM1) ADF motor(M1) Pickup clutch(CL1) LED PCB(PCB3) [13] [12] F-2-8... -

Page 19: Drive Configuration

Technology > Basic Configuration (ADF) > Drive Configuration Drive Configuration ■ Sensor Layout SR10 SR12,SR13,SR14,SR15 SR11 F-2-9 Component part Detection content Jam detection Delay Stationary Others SR1 Registration sensor Registration arch creation timing YES SR2 Read sensor Registration arch creation timing YES SR3 Delivery reversal sensor Delivery reversal timing SR4 Timing sensor... -

Page 20: Controls (Adf)

Technology > Controls (ADF) > Outline of Operation Modes > Forward Pickup/Delivery Operation Controls (ADF) ■ Forward Pickup/Delivery Operation • Simplex read operation (when two document sheets are placed) Electric Circuit Diagram The control of this equipment is performed on the reader controller PCB. Following shows the relation of each electrical parts. - Page 21 Technology > Controls (ADF) > Outline of Operation Modes > Forward Pickup/Reverse Delivery Operation 2-10 ■ Forward Pickup/Reverse Delivery Operation • Duplex read operation (when two document sheets are placed) Document Completion of reading of Completion of reading of Start of reading of front side first document sheet second document sheet of first document sheet...

- Page 22 Technology > Controls (ADF) > Outline of Operation Modes > Forward Pickup/Reverse Delivery Operation 2-11 Stop after feeding the first Removal of registration loop of End of reading of front side Start of separation of second document sheet to reversal reverse side of first document of second document sheet document sheet and pressurization...

-

Page 23: Document Pickup/Separation

Technology > Controls (ADF) > Document Pickup/Separation > Basic Pickup Operation 2-12 Document Pickup/Separation ■ Basic Pickup Operation With a document placed on the document tray, pressing the print start key will pick up the document in the following manner. Pickup operation When the pickup/feed motor (M1) turns in reverse direction, the pickup roller unit lowers to rotate the pickup rollers, thus feeding the document. - Page 24 Technology > Controls (ADF) > Document Pickup/Separation > Pickup Unit and Stopper 2-13 Feed ■ Pickup Unit and Stopper The pickup/feed motor (M1) turns in the reverse direction to drive the registration clutch (CL2), The pickup unit consists of a pickup roller and feed roller. thus allowing the registration roller to feed the document.

-

Page 25: Document Reversing

Technology > Controls (ADF) > Document Reversing > Basic Operation 2-14 Document Reversing Reversal/feed 1 When the trailing edge of the fed document moves past the delivery reversal sensor (SR3), ■ Basic Operation the pickup/feed motor stops. Immediately after this, the pickup/feed motor starts turning in the reverse direction to feed the document to the registration roller, then it stops. -

Page 26: Document Feeding/Delivery

Technology > Controls (ADF) > Document Feeding/Delivery > Release Operation 2-15 Document Feeding/Delivery ■ Release Operation When a document is read, the read roller 1 (lower driven rollers) are pressurized/released to ■ Basic Operation prevent the training edge of the document from swaying. After completion of stream reading on the document glass, the document is delivered to the After separation of the document, the read roller 1 (lower driven rollers) are pressurized by document delivery unit as discussed below. -

Page 27: Document Detection

Technology > Controls (ADF) > Document Detection > Initial Document Size Detection 2-16 Document Detection ■ Initial Document Size Detection The document length sensor 1 (SR7) and document length sensor 2 (SR10) detect the ■ Outline longitudinal size of the document placed on the document tray, and the document width This machine detects a document using either of the two methods depending on the print volume (VR1) and A4R/LTRR identification sensor (SR8) detect the lateral size of the mode. - Page 28 Technology > Controls (ADF) > Document Detection > Mixed width document size detection 2-17 The following table shows the relationship among length detection sensor signals, ■ Mixed width document size detection document widths, and initial document sizes. The document of the most wide width doing mix width document detects it in document Document width detection Document length Detected size...

-

Page 29: Detecting Jams

Technology > Controls (ADF) > Detecting Jams > Jams 2-18 Detecting Jams ■ Mixed width document combination • Outline ■ Jams Different width (in the main scanning direction) originals can be loaded. This machine detects document jams using the sensors shown below. •... -

Page 30: Power Supply

Technology > Controls (ADF) > Stamp Operation > Outline 2-19 Stamp Operation ACC ID JAM Code JAM Type Sensor Name Sensor ID 0003 DELAY Registration sensor ■ Outline 0004 STNRY Registration sensor 0005 DELAY Read sensor If the stamp function is selected in the FAX mode of the host machine, the stamp solenoid 0006 STNRY Read sensor... -

Page 31: Fan

Technology > Controls (ADF) > Work of service > When replacing the parts 2-20 Work of service ■ Fan Operation ■ When replacing the parts The fan (FM1) mounted on this machine always operates at full speed from the time ADF This machine has the following adjustment items. - Page 32 Technology > Controls (ADF) > Work of service > Periodic Servicing 2-21 ■ User Maintenance ■ Periodic Servicing a.Cleaning When the parts are reaching the expected service life, perform the parts replacement or Tell the user to clean the following parts every 2000 sheets. cleaning etc if needed.

-

Page 33: Periodic Servicing

Periodic Servicing ■ List of Work for Scheduled Servicing (Reader) ■ List of Work for Scheduled Servicing (ADF) Periodic Servicing... - Page 34 Periodic Servicing > List of Work for Scheduled Servicing (Reader) List of Work for Scheduled Servicing (Reader) CL: Cleaning LU: Lubricate AD: Adjustment CH: Inspection Work Interval Parts name Parts No. Number Reference Installation timely Copyboard glass (Surface) FL2-9792-000 Copyboard glass (Surface/Back) Including the white plate positioning of the glass surface.

- Page 35 Periodic Servicing > List of Work for Scheduled Servicing (Reader) Scanner rail Scanner rail Scanner shaft Scanner shaft F-3-2 Periodic Servicing > List of Work for Scheduled Servicing (Reader)

- Page 36 Periodic Servicing > List of Work for Scheduled Servicing (ADF) List of Work for Scheduled Servicing (ADF) As for the user maintenance point as well, clean it at the time of the periodic maintenance. PR:Replacement (Periodically replaced parts) CR:Replacement (consumable parts) CL:Cleaning LU:Lubrication AD:Adjustment CH:Maintenance Part name Part number Work interval...

-

Page 37: Parts Replacement And Cleaning Procedure

Parts Replacement and Cleaning Procedure ■ Parts Replacement and Cleaning Procedure Parts Replacement and Cleaning Procedure... -

Page 38: Removing The Reader Controller Pcb

Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Removing the Reader Controller PCB > Procedure Parts replacement and cleaning procedure 4) Disconnect the connector [1] from the Reader Controller PCB. 5) Remove the 2 Flat Cables [2] from the Reader Controller PCB. •... - Page 39 Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Removing the Reader Controller PCB > Procedure 7) Remove the Reader Controller PCB Cover Plate [1]. 10) Remove the Reader Controller PCB [1]. • 4 Screws [2] • 4 Screws [2] F-4-5 F-4-7 8) Remove the Flat Cable [2] from the Reader Controller PCB [1].

-

Page 40: Cleaning The Reader Scanner Mirors

Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Cleaning the Reader Scanner Mirors > Procedure Cleaning the Reader Scanner Mirors CAUTION: Grease is applied on the 2 Rail Shafts [1] of the Reader Scanner Unit. If you have ■... - Page 41 Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Cleaning the Reader Scanner Mirors > Procedure 6) Move the Reader Scanner Unit in the direction of the arrow while paying attention not to make it contact with the frame of the Reader, and place it as shown in the figure below. Loosen F-4-10 F-4-11...

-

Page 42: Removing The Reader Scanner Unit

Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Removing the Reader Scanner Unit > Procedure Removing the Reader Scanner Unit 8) Return the Scanner Unit to its original position. 9) Clean the 4 mirors [1] ■ Procedure 1) Remove the ADF Unit [1]. - Page 43 Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Removing the Reader Scanner Unit > Procedure CAUTION: Grease is applied on the 2 Rail Shafts [1] of the Reader Scanner Unit. If you have touched the grease, be careful not to put it to other parts. Loosen F-4-16 CAUTION: Holding the Reader Scanner Unit...

- Page 44 Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Removing the Reader Scanner Unit > Procedure 6) Disconnect the Flat Cable [1] (with Protection Sheet [2]) from the Reader Scanner Unit. • 1 Connector (with a hook) [3] •...

- Page 45 Parts Replacement and Cleaning Procedure > Parts replacement and cleaning procedure > Removing the Reader Scanner Unit > Procedure Installation Procedure When installing the belt to the Reader Scanner Unit, it can be installed easily by removing the belt from pulley. F-4-18 Parts Replacement and Cleaning Procedure >...

-

Page 46: List Of Parts (Adf)

Parts Replacement and Cleaning Procedure > List of Parts (ADF) > Consumable Parts Requiring Periodic Replacement and Cleaning Points 4-10 List of Parts (ADF) Consumable Parts Requiring Periodic Replacement and Cleaning Points External Covers Rear small cover Rear cover Feeder cover Front cover F-4-19 Part name... -

Page 47: List Of Clutchs, Solenoids, Motors, Fans, Pcbs

Parts Replacement and Cleaning Procedure > List of Parts (ADF) > Others 4-11 List of Clutchs, Solenoids, Motors, Fans, PCBs Others PCB1 Right hinge Left hinge PCB3 PCB4 (SR12〜SR15) Platen roller F-4-21 F-4-22 Part name Part number Reference ADF motor Part name Part number Reference... -

Page 48: List Of Sensors

Parts Replacement and Cleaning Procedure > List of Parts (ADF) > List of Sensors 4-12 List of Sensors SR10 SR15 SR14 SR13 SR12 SR11 F-4-23 Part name Part number Reference Registration sensor Read sensor Delivery reversal sensor Timing sensor Document set sensor Cover open/closed sensor Document length sensor 1 A4R/LTRR identification sensor... -

Page 49: Main Units (Adf)

Parts Replacement and Cleaning Procedure > Main Units (ADF) > Removing the Feed Unit 4-13 Main Units (ADF) 7) Remove the rear cover."Removing the Rear Cover"(page 4-16). 8) Disconnect the eight connectors from the ADF driver PCB. Removing the Feed Unit 1) Remove the ADF from the host machine. - Page 50 Parts Replacement and Cleaning Procedure > Main Units (ADF) > Removing the Feed Unit 4-14 12) Remove the harness guide. CAUTION: - Connector 5 pcs. - Screw 1 pc. When install ADF to a host machine after exchange work, adjustment of eight items is need.

-

Page 51: External Covers (Adf)

Parts Replacement and Cleaning Procedure > External Covers (ADF) > Removing the Front Cover 4-15 External Covers (ADF) 3) Open the ADF. 4) Remove the front cover. - Screw 2 pcs. Removing the Front Cover 1) Open the feeder cover. F-4-32 F-4-30 2) Remove the screw. -

Page 52: Removing The Rear Cover

Parts Replacement and Cleaning Procedure > External Covers (ADF) > Removing the Feeder Cover 4-16 Removing the Rear Cover Removing the Feeder Cover 1) Open the feeder cover. 1) Open the feeder cover. 2) Move to the back of the host machine and detach the rear small cover. 2) Remove the rear cover and rear small cover."Removing the Rear Cover"(page 4-16). -

Page 53: Removing The Inner Cove

Parts Replacement and Cleaning Procedure > External Covers (ADF) > Removing the inner cove 4-17 Removing the inner cove 7) Remove the feeder cover. - Screw 1 pc. 1)Open the feeder cover. - Positioning pin 1 pc. 2)Remove the inner cover from the feeder cover. -Hook 2 pcs. -

Page 54: Removing The White Plate

Parts Replacement and Cleaning Procedure > External Covers (ADF) > Removing the white plate 4-18 Removing the white plate 7) Close the DADF, and then open it again. 1) Open the ADF. 2) Remove the white plate. F-4-41 8) Press the white plate upward as shown in the figure below. CAUTION: If the white plate is pressed downward, it is placed on the index sheet, so be sure to F-4-39... - Page 55 Parts Replacement and Cleaning Procedure > External Covers (ADF) > Removing the white plate 4-19 9) With the DADF closed, check that the white plate is not placed on the Index sheet as shown in the figures. CAUTION: Be sure that there is no gap between the white plate and the index sheet. As a guide, it should be 0.3 mm or less.

-

Page 56: Consumable Parts Requiring Periodic Replacement And Cleaning Points (Adf)

Parts Replacement and Cleaning Procedure > Consumable Parts Requiring Periodic Replacement and Cleaning Points (ADF) > Removing the Separation Pad 4-20 Consumable Parts Requiring Periodic Replacement Removing the Separation Pad and Cleaning Points (ADF) 1)Open the feeder cover. 2)Remove two hooks to remove the separation pad. -Hook 2 pcs. -

Page 57: Replacing The Stamp

Parts Replacement and Cleaning Procedure > Consumable Parts Requiring Periodic Replacement and Cleaning Points (ADF) > Exchanging the Feed Guide 4-21 Replacing the Stamp Exchanging the Feed Guide 1)Open the feeder cover and separation guide. 1) Open the ADF. 2) Using tweezers, remove the stamp 2) Remove the feed guide . -

Page 58: Clutch Solenoid Motor Fan Pcb (Adf)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Release Motor(M2) 4-22 Clutch Solenoid Motor Fan PCB (ADF) Removing the Release Motor(M2) 1) Open the feeder cover. Removing the ADF Motor(M1) 2) Open the ADF. 3) Detach the front cover."Removing the Front Cover"(page 4-15). -

Page 59: Removing The Pressurization Solenoid(Sl1)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Pickup Clutch/Registration Clutch(CL1/CL2) 4-23 Removing the Pressurization Solenoid(SL1) Pickup Clutch/Registration Clutch(CL1/CL2) 1) Open the feeder cover. 1) Open the feeder cover. 2) Remove the rear cover."Removing the Rear Cover"(page 4-16). 2) Remove the rear cover."Removing the Rear Cover"(page 4-16). -

Page 60: Removing The Adf Driver (Pcb1)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the LED PCB (PCB3) 4-24 Removing the ADF Driver (PCB1) 4) Remove the clutch - Resin ring 1 pc 1) Open the feeder cover. - Bearing 1 pc 2) Remove the rear cover and rear small cover."Removing the Rear Cover"(page 4-16). -

Page 61: Removing The Different Width Sensor Pcb(Pcb4)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Different Width Sensor PCB(PCB4) 4-25 Removing the Different Width Sensor PCB(PCB4) 7) Remove the LED PCB. - Screw 1 pc 1) Open the feeder cover. - Connector 1 pc 2) Open the DADF. -

Page 62: Removing The Fan

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Sensor(SR1,SR2,SR3) 4-26 Removing the Fan Removing the Sensor(SR1,SR2,SR3) 1) Open the feeder cover. 1) Remove the feed unit."Removing the Feed Unit"(page 4-13). 2) Remove the rear cover."Removing the Rear Cover"(page 4-16). - Page 63 Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Sensor(SR1,SR2,SR3) 4-27 4) Remove the resin ring, pulley, gear, E-ring, and bearing.(A position) 5) While pushing the hook in the direction of the arrow, remove the platen roller unit in the Remove the support plate,three gears and bearing.

- Page 64 Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Sensor(SR1,SR2,SR3) 4-28 6)Remove the cover 7) Remove the read roller 2 - Screw 2 pcs. - Resin ring 1 pc. - Pulley 1 pc. - Gear 2 pcs. - E-ring 1 pc.

-

Page 65: Removing The Timing Sensor(Sr4)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Document Set Sensor(SR5) 4-29 Removing the Timing Sensor(SR4) 8) Remove the sensor mount - Hook 2 pcs. 1) Open the feeder cover. - Screw 2 pcs. 2) Remove the rear cover."Removing the Rear Cover"(page 4-16). -

Page 66: Removing The Cover Open/Closed Sensor(Sr6)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Document Length Sensor(SR7,SR10) 4-30 Removing the Cover Open/Closed Sensor(SR6) Removing the Document Length Sensor(SR7,SR10) 1) Open the feeder cover. 1) Detach the cover on the reverse side of the document tray. 2) Remove the rear cover."Removing the Rear Cover"(page 4-16). -

Page 67: Removing The A4R/Ltrr Identification Sensor(Sr8)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Release Motor HP Sensor(SR11) 4-31 Removing the A4R/LTRR Identification Sensor(SR8) Removing the Release Motor HP Sensor(SR11) 1) Detach the cover on the reverse side of the document tray.(Refer to page 4-30) 1) Open the feeder cover. -

Page 68: Removing The Document Width Volume(Vr1)

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the hinge > Removing the left hinge 4-32 Removing the Document Width Volume(VR1) Removing the hinge ■ Removing the left hinge 1) Detach the cover on the reverse side of the document tray.(Refer to page 4-30) 2) Remove the document width volume unit. -

Page 69: Removing The Platen Roller

Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Platen roller 4-33 Removing the Platen roller ■ Removing the Right hinge 1) Remove the DADF from the host machine. 1) Remove the feed unit."Removing the Feed Unit"(page 4-13). 2) Reverse ADF. - Page 70 Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Platen roller 4-34 4) Remove the resin ring, pulley, gear, E-ring, and bearing.(A position) 5) While pushing the hook in the direction of the arrow, remove the platen roller unit in the ...

- Page 71 Parts Replacement and Cleaning Procedure > Clutch Solenoid Motor Fan PCB (ADF) > Removing the Platen roller 4-35 7) Remove the Platen roller. -Resin ring 1 pc -Platen roller holder(left) 1 pc -Platen roller holder(right) 1 pc -Screw 2 pcs F-4-83 CAUTION: When install DADF to a host machine after exchange work, adjustment of eight items...

-

Page 72: Adjustment

Adjustment ■ Adjustment (Reader) ■ Overview (ADF) ■ Adjustment Method (ADF) Adjustment... -

Page 73: Service Mode Backup

Adjustment > Adjustment (Reader) > Measurement during Reader Controller PCB Replacement and After RAM Clear: Adjustment (Reader) Measurement during Reader Controller PCB Replacement and After RAM Clear: Service mode backup The machine is adjusted one by one at the factory shipment and the adjustment values are Points to note before replacing the Reader Controller PCB: written on the service label. - Page 74 Adjustment > Adjustment (Reader) > Measurement during Reader Controller PCB Replacement and After RAM Clear: When backup is not performed normally 8) Adjust tray width. Perform either AB system or Inch system. 4) Enter the values written on the service label (on the back of the Reader Front Cover). a.

-

Page 75: After Replacing The Scanner Unit (Reader Side)

Adjustment > Adjustment (Reader) > After Replacing the Scanner Unit (Reader side) After Replacing the Scanner Unit (Reader side) 3-2) Perform service mode item. COPIER > FUNCTION > CCD > DF-WLVL1 NOTE: T-5-16 The adjustment method differs depending whether the unit replaced is Reader Scanner 3-3) Remove the paper from copyboard glass, set it in the DADF document pickup tray. -

Page 76: After Replacing The Scanner Unit

Adjustment > Adjustment (Reader) > After Replacing the Scanner Unit After Replacing the Scanner Unit COPIER > FUNCTION > CCD > DF-WLVL2 1) Input the white level data (barcode value in the copyboard glass right upper) of the T-5-26 standard white plate. 3-5) Again, Set A4 or LTR paper in the copyboard glass, close the DADF. -

Page 77: Overview (Adf)

Adjustment > Adjustment Method (ADF) > Preparation or Creation of Test Chart Overview (ADF) Adjustment Method (ADF) Preparation or Creation of Test Chart This machine has the following adjustment items. Carry out each adjustment after replacing the relevant parts. Prepare a test chart. If there is no test chart, create a test chart. Adjustment type Parts to replace Remarks... -

Page 78: Adjusting The Height Of The Hinge

Adjustment > Adjustment Method (ADF) > Adjusting the Height of the hinge > Check the height of the left hinge Adjusting the Height of the hinge ■ Check the height of the left hinge ■ Pre-check Checking the rear-left height of the ADF. Cut a sheet of A4 paper(use plain paper) to make a paper slip with width of 45mm. - Page 79 Adjustment > Adjustment Method (ADF) > Adjusting the Height of the hinge > Adjust the height of the left hinge 3) Checking the front-left height of the ADF. ■ Adjust the height of the left hinge Set paper against the protrusions of the stream reading glass in such a manner that the Adjust the height with the left hinge height adjusting screw.

-

Page 80: Adj Of Dadf Tray Width

Adjustment > Adjustment Method (ADF) > Adj of DADF Tray width > Inch-Configuration Adjustment Adj of DADF Tray width ■ Adjust the height of the right hinge If the height is improper, adjust it with the right hinge adjusting screw. NOTE: The result of this adjustment is retained on the reader controller PCB. -

Page 81: Adjusting The Perpendicularity

Adjustment > Adjustment Method (ADF) > Adjusting the Perpendicularity 5-10 Adjusting the Perpendicularity Loosen the screw securing the right hinge. Load a test chart in the DADF to make a copy. NOTE: The test chart is printed on the back cover of the Installation Procedure (this manual). Copy it or clip it out. -

Page 82: Scan Position Auto Adj In Dadf Mode

Adjustment > Adjustment Method (ADF) > Adj img pstn in DADF mode:horz scan 5-11 Scan position auto adj in DADF mode Adj img pstn in DADF mode:horz scan Start service mode. Place the test chart in the ADF, and make a copy. On the Service Mode screen, touch the following notations in sequence to bring up the Compare the copy against the Test Chart for the horizontal registration;... -

Page 83: Adj Of Dadf Img Lead Edge Margin: Front

Adjustment > Adjustment Method (ADF) > Fine adj of DADF image magnifictn: front 5-12 Adj of DADF img lead edge margin: front Fine adj of DADF image magnifictn: front Place the Test Chart in the ADF, and make a copy. Place the Test Chart in the ADF, and make a copy. -

Page 84: White Level Adj

Adjustment > Adjustment Method (ADF) > White level adj 5-13 White level adj 12) Remove the paper from the copyboard glass, and place it on the original tray of the ADF. 13) Press [DF-WLVL4] on the touch panel to highlight. 14) Press [OK]. -

Page 85: Installation

Installation ■ How to check this Installation procedure ■ Checking the Content ■ Caution during installation ■ Turning OFF the host machine power ■ Preparation for Installation in the Host Machine ■ Preparation for the Reader Unit Installation ■ Installation procedure ■... -

Page 86: When Using The Parts Included In The Package

Installation > Points to Note before Installation How to check this Installation procedure Product Name Safety regulations require the product's name to be registered. In some regions where this When using the parts included in the package product is sold, the following names in parenthesis may be registered instead. •... -

Page 87: Checking The Contents

Installation > Checking the Contents Checking the Contents [13] Stamp Cartridge X 1 [14] Handle X 1 [15] ADF Cable Seal X 1 Refer to Chart Refer to Chart [1] Reader Unit X 1 [2] Reader Left Cover X 1 [3] Reader Right Cover X 1 [16] Face Seal X 8 [17] Rubber Cap X 6... -

Page 88: Turning Off The Host Machine

Installation > Installation Outline Drawing <CD/Guides> Label name For Europe (ENV) Except for Europe (ENV) • Instruction sheet at the time of machine delivery Duplex Duplex Duplex Duplex Duplex Duplex Color Color Color Color Color Color Image Image Image Image Image Image Reader... -

Page 89: Before Installing: Preparation On The Host Machine Side

Installation > Before Installing: Preparation on the Host Machine Side 3) Remove the Right Rear Cover 1. • 1 Screw (RS Tightening; M4) • 2 Screws (TP; M3) Before Installing: Preparation on the Host Machine • 1 Claw Side 1) Remove the Left Rear Cover. •... -

Page 90: Before Installing: Preparation On The Reader Unit Side

Installation > Before Installing: Preparation on the Reader Unit Side Before Installing: Preparation on the Reader Unit 5) Move the Control Panel in the direction of the arrow. Side CAUTION: • Be sure not to discard the packaging box since it will be used to place the Reader Unit temporarily. - Page 91 Installation > Before Installing: Preparation on the Reader Unit Side CAUTION: 2) Temporarily place the equipment taken out from the box, and change the holding position. Be sure not to remove the tape and the 2 Fixation Screws of the Scanner System. 4) Remove the tapes affixed to the outside of the Reader Unit and the packaging materials.

- Page 92 Installation > Before Installing: Preparation on the Reader Unit Side 5) Open the ADF or the Copyboard Cover, and remove the tapes affixed to the copyboard 7) Connect the Reader Power Supply Cable. and the packaging materials. • 1 Reuse Band CAUTION: NOTE: When the Reuse Band of the Reader Power Supply Cable does not reach the position...

-

Page 93: Installation Procedure

Installation > Installation Procedure Installation Procedure 8) Secure the Reader Communication Cable temporarily with the tape removed in step 4 to prevent it from being trapped. CAUTION: How to hold the Reader Unit • When lifting the Reader Unit, be sure to work with 2 or more people. Also, be sure to lift the equipment horizontally. - Page 94 Installation > Installation Procedure 6-10 2) Secure the left side of the Reader Unit. 4) Secure the front side of the Reader Unit. • 1 Boss • 1 Boss • 4 Screws (Binding; M4x8) • 2 Screws (Binding; M4x8) NOTE: Boss Be sure to tighten the rearmost screw first.

- Page 95 Installation > Installation Procedure 6-11 6) Route the harness. 8) Remove the tape, and remove the Scanner System Fixation Screws. • Guide • 2 Screws • 2 Wire Saddles NOTE: Be sure to keep the 2 Scanner System Fixation Screws to use at the time of delivery. F-6-26 7) Remove the handle.

- Page 96 Installation > Installation Procedure 6-12 Install the Left Rear Cover. Open the Right Lower Cover, and install the Right Rear Cover 1. • 5 Claws • 1 Screw (RS Tightening; M4) • 2 Screws • 2 Screws (TP; M3) • 2 Rubber Caps •...

- Page 97 Installation > Installation Procedure 6-13 Install the Reader Front Cover. Install the Reader Left Cover. • 1 Hook • 3 Hooks • 2 Protrusions • 2 Screws (2 Screws that removed in step 7) • 2 Screws • 2 Rubber Caps •...

-

Page 98: Install The Stamp Cartridge

Installation > Install the Stamp Cartridge > For [Duplex Color Image Reader Unit-B1] 6-14 Install the Stamp Cartridge 4) Using tweezers, install the Stamp Cartridge with its stamp side faces up. NOTE: Stamp Cartridge installation procedure varies depending on the type of the Reader unit. For [Duplex Color Image Reader Unit-B1] 1) Open the ADF. -

Page 99: For [Color Image Reader Unit-B1]

Installation > Affixing the Label 6-15 For [Color Image Reader Unit-B1] Affixing the Label 1) Open the Feed Cover and the Separation Guide of the DADF. 1) Affix the labels according to the location over the existing ones. • Hinge Label (only for Duplex Color Image Reader Unit-E1 and Color Image Reader Unit-F1) •... -

Page 100: Setting After Installation

Installation > Auto Gradation Adjustment 6-16 Setting after Installation Auto Gradation Adjustment Execute the following setting after installing the host machine. Execute the auto gradation adjustment to the following 3 modes: [Plain], [Heavy 1/Heavy 2], and [Heavy 3]. However, when using 2 or more types of paper, it is necessary to execute all the modes 1) Connect the power plug of the host machine to the outlet. -

Page 101: Appendix

Appendix ■ Service Tools ■ General Circuit Diagram... - Page 102 Appendix > Service Tools > Special Tools Service Tools Special Tools In addition to the standard tools set, the following special tools are required when servicing the machine: Tool Name Tool No. Rank Figure Use/Remarks Digital multi meter FY9-2002-000 Electric check, etc T-7-1 Reference: Category A: Must be kept by each service engineer.

- Page 103 General Circuit Diagram General Circuit Diagram_Reader LED_UNIT_R LED_UNIT_L J2403 J2402 ADF open/closed Scanner unit ADF open/closed Reader scanner Original size Original size J2401 sensor 2 home position sensor sensor 1 motor sensor 1 sensor 2 Reader Scanner Unit J2101 J5003 J5002 J5001 J5004...

-

Page 104: Adf Driver Pcb

General Circuit Diagram_ADF Registration Pickup Release motor Registration Document set clutch Delivery reversal ADF Fan clutch ADF motor sensor sensor sensor Cover open/closed Timing sensor sensor Read sensor J104 J164 J164H J157 J167 J101 J151 J201 J102 J152 J202 J114 J107H J117H J107... - Page 105 ADF Driver PCB ADF Driver PCB 1/5 +3.3V MOT_I2 +3.3V SCLK +3.3V CP128 check +3.3V CP129 CP65 CP121 VOUT check check check CP112 check +3.3V VDD3-1 VSS-4 +3.3V CAS_IN LOAD_BLK_NUM[0] CP53 VDD-1 MULTI_PORT[31] CP14 CP52 check MULTI_PORT[40] MULTI_PORT[30] CP15 CP51 check check MULTI_PORT[41]...

- Page 106 ADF Driver PCB 2/5 R108 CP107 +3.3V J19P check J19P CP116 REG_SEN check CP66 R125 CP67 R109 CP78 J19P check check J19P check CP108 RD_SEN R119 check +3.3V J19P J19P CP77 CP101 J19P check check R120 TRAY_VOL J19P +3.3V J19P CP70 CP99 J19P...

- Page 107 ADF Driver PCB 3/5 +24V R137 MOT_CLK (ACOM) MOT_CWB CP134 CP79 R118 MOT_ENB check check R101 R138 (/B) COVER_SEN (BCOM) check check CP137 CP136 +3.3V (/A) MOT_I0 R122 CP115 ETH1 check MOT_I1 R121 CP114 check MOT_I2 CP23 CP113 check check +3.3V CP74 CP75...

- Page 108 VIII ADF Driver PCB 4/5 +24V R132 CP98 check +3.3V CP73 CP71 check CP94 check check PGND CP80 CP93 VREG5 NC10 check check ATT2 GND3 CP92 ATT1 CP81 CP91 check CP76 check check OUT1A CP83 check check CP84 RCHOP OUT1B (/A) CP85 check...

- Page 109 ADF Driver PCB 5/5 +3.3V +3.3V J10P J10P CP82 REG_SEN TIMING_SEN check R100 J10P J10P CP96 RD_SEN J10P check EMPTY_SEN J10P J10P EXIT_SEN J10P COVER_SEN J10P J10P +3.3V J13P J13P CP135 CP100 R116 R115 SIZE_L1_SEN J13P check check SET_LED J13P +3.3V J13P A4/LTR_SEN...

-

Page 110: Led Board

LED Board LED Board J193 LED1 J193 J193... -

Page 111: Different Width Sensor Pcb

Different width sensor PCB Different width sensor PCB +3.3V J115 J115 J115 J115 J115 J115...