Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric FR-E540-0.4K-EC

- Page 1 TRANSISTORIZED INVERTER FR-E INSTRUCTION MANUAL HIGH PERFORMANCE & HIGH FUNCTION FR-E540-0.4K to 7.5K-EC FR-E520S-0.4K to 2.2K-EC OUTLINE Chapter 1 INSTALLATION Chapter 2 AND WIRING OPERATION/ Chapter 3 CONTROL PARAMETERS Chapter 4 PROTECTIVE Chapter 5 FUNCTIONS SPECIFICATIONS Chapter 6...

- Page 2 Thank you for choosing the Mitsubishi Transistorized inverter. This instruction manual gives handling information and precautions for use of this equipment. Incorrect handling might cause an unexpected fault. Before using the inverter, please read this manual carefully to use the equipment to its optimum. Please forward this manual to the end user.

- Page 3 SAFETY INSTRUCTIONS 1. Electric Shock Prevention WARNING z While power is on or when the inverter is running, do not open the front cover. You may get an electric shock. z Do not run the inverter with the front cover removed. Otherwise, you may access the exposed high-voltage terminals or the charging part of the circuitry and get an electric shock.

- Page 4 3. Injury Prevention CAUTION z Apply only the voltage specified in the instruction manual to each terminal to prevent damage etc. z Ensure that the cables are connected to the correct terminals. Otherwise, damage etc. may occur. z Always make sure that polarity is correct to prevent damage etc. z While power is on and for some time after power-off, do not touch the inverter or brake resistor as they are hot and you may get burnt.

- Page 5 ( 2 ) Wiring CAUTION z Do not fit capacitive equipment such as power factor correction capacitor, radio noise filter or surge suppressor to the output of the inverter. z The connection orientation of the output cables U, V, W to the motor will affect the direction of rotation of the motor.

- Page 6 CAUTION z The electronic overcurrent protection does not guarantee protection of the motor from overheating. z Do not use a magnetic contactor on the inverter input for frequent starting/stopping of the inverter. z Use a noise filter to reduce the effect of electromagnetic interference. Otherwise nearby electronic equipment may be affected.

-

Page 7: Table Of Contents

CONTENTS 1 OUTLINE 1.1 Pre-Operation Information..................1 1.1.1 Precautions for operation..................1 1.2 Basic Configuration ....................3 1.2.1 Basic configuration ....................3 1.3 Structure........................4 1.3.1 Appearance and structure ................... 4 1.3.2 Removal and reinstallation of the front cover ............5 1.3.3 Removal and reinstallation of the wiring cover ............ - Page 8 3 OPERATION/CONTROL 3.1 Pre-Operation Information..................47 3.1.1 Types of operation modes ................. 47 3.1.2 Power on......................49 3.2 About the Control Panel ................... 50 3.2.1 Names and functions of the control panel (FR-PA02-02) ........50 3.2.2 Control panel mode is changed by pressing the key ........

- Page 9 4.2.7 DC injection brake (Pr. 10 to Pr. 12) ..............77 4.2.8 Starting frequency (Pr. 13)................. 78 4.2.9 Load pattern selection (Pr. 14) ................79 4.2.10 Jog operation (Pr. 15, Pr. 16) ................80 4.2.11 Stall prevention (Pr. 22, Pr. 23, Pr. 66) ............81 4.2.12 Acceleration/deceleration pattern (Pr.

- Page 10 4.2.42 Actual operation hour meter clear (Pr. 171)........... 142 4.2.43 Input terminal function selection (Pr. 180 to Pr. 183)........142 4.2.44 Output terminal function selection (Pr. 190 to Pr. 192)........144 4.2.45 Cooling fan operation selection (Pr. 244) ............145 4.2.46 Slip compensation (Pr.

- Page 11 5.3.7 Replacement of parts..................174 5.3.8 Measurement of main circuit voltages, currents and powers......178 6 SPECIFICATIONS 6.1 Standard Specifications ..................180 6.1.1 Model specifications ..................180 6.1.2 Common specifications..................182 6.1.3 Outline drawings ....................184 APPENDIX Appendix 1 Data Code List................... 186...

- Page 12 C H A P T E R 1 CHAPTER 1 O U T L I N E OUTLINE This chapter gives information on the basic "outline" of this product. Always read the instructions before using the equipment. 1.1 Pre-Operation Information .......... 1 C hapter 1 1.2 Basic Configuration.............

-

Page 13: Pre-Operation Information

1) Inverter type Rating plate Capacity plate MITSUBISHI INVERTER Capacity plate Inverter MODEL FR-E540-0.4K-EC type Input rating INPUT XXXXX FR-E540-0.4K-EC Output rating OUTPUT : XXXXX Serial number... - Page 14 OUTLINE (2) Preparation of instruments and parts required for operation Instruments and parts to be prepared depend on how the inverter is operated. Prepare equipment and parts as necessary. (Refer to page 47.) (3) Installation To operate the inverter with high performance for a long time, install the inverter in a proper place, in the correct direction, with proper clearances.

-

Page 15: Basic Configuration

1.2 Basic Configuration OUTLINE 1.2 Basic Configuration 1.2.1 Basic configuration The following devices are required to operate the inverter. Proper peripheral devices must be selected and correct connections made to ensure proper operation. Incorrect system configuration and connections can cause the inverter to operate improperly, its life to be reduced considerably, and in the worst case, the inverter to be damaged. -

Page 16: Structure

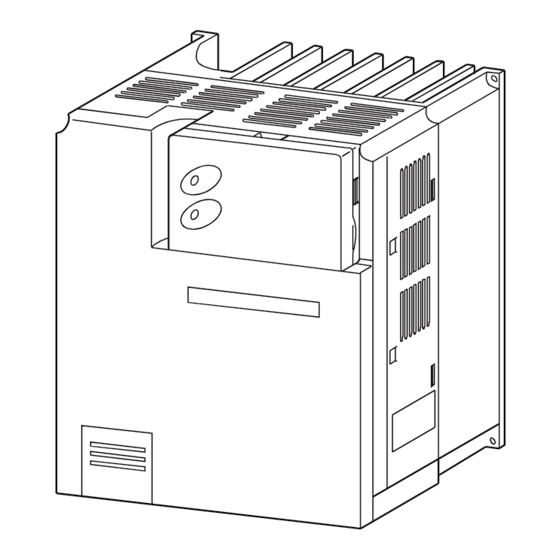

1.3 Structure OUTLINE 1.3 Structure 1.3.1 Appearance and structure (1) Front view Accessory cover Front cover Capacity plate Rating plate Wiring port cover for option (2) Without front cover and accessory cover PU connector* Inboard option mounting position POWER lamp (yellow) ALARM lamp (red) Connector for connection of inboard option... -

Page 17: Removal And Reinstallation Of The

OUTLINE 1.3.2 Removal and reinstallation of the front cover z Removal The front cover is fixed with catches in positions A, B and C. Push A and B in the directions of arrows at the same time and remove the cover using C as supporting points. -

Page 18: Removal And Reinstallation Of The Wiring Cover

OUTLINE 1.3.3 Removal and reinstallation of the wiring cover z Removal Remove the wiring cover by pulling it in the direction of arrow A. Wiring hole z Reinstallation Pass the cables through the wiring hole and reinstall the cover in the original position. -

Page 19: Removal And Reinstallation Of The Accessory Cover

OUTLINE 1.3.4 Removal and reinstallation of the accessory cover z Removal Hold down the portion A indicated by the arrow and lift the right hand side using the portion B indicated by the arrow as a support, and pull out the accessory cover to the right. -

Page 20: Reinstallation And Removal Of The Control Panel

OUTLINE 1.3.5 Reinstallation and removal of the control panel To ensure safety, reinstall and remove the optional control panel (FR-PA02- ) after switching power off. The charging area and control printed board are exposed on the rear surface of the control panel. - Page 21 OUTLINE z Using the connection cable for operation 1) Fit the rear cover option FR-E5P to the back surface of the control panel. 2) Securely plug one end of the connection cable into the PU connector of the inverter and the other end into the adaptor of the FR-E5P option to connect it to the control panel.

-

Page 22: Removal Of The Operation Panel (Fr-Pa02-02)

OUTLINE 1.3.6 Removal of the operation panel (FR-PA02- ) front cover 1) Open the control panel front cover to 90 degrees. 2) Pull out the control panel front cover to the left to remove it. 90 degrees 1.3.7 Exploded view Control panel(FR-PA02- Front cover Accessory... - Page 23 CHAPTER 2 INSTALLATION AND INSTALLATION AND WIRING WIRING This chapter gives information on the basic "installation and wiring" for use of this product. Always read the instructions in this chapter before using the equipment. 2.1 Installation ..............11 C hapter 1 2.2 Wiring ................13 2.3 Other Wiring ..............32 C hapter 2...

-

Page 24: Installation And Wiring

2.1 Installation INSTALLATION AND WIRING 2 INSTALLATION AND WIRING 2.1 Installation 2.1.1 Instructions for installation 1) Handle the unit carefully. The inverter uses plastic parts. Handle it gently to protect it from damage. Also, hold the unit with even strength and do not apply too much strength to the front cover alone. - Page 25 INSTALLATION AND WIRING 3) Note on ambient 4) Clearances around the inverter temperatures 10cm Leave sufficient or more Cooling air clearances above and under the Measurement inverter to ensure position adequate ventilation. Cooling fan FR-E500 1cm or 1cm or FR-E500 built in the more* more*...

-

Page 26: Wiring

2.2 Wiring INSTALLATION AND WIRING 2.2 Wiring 2.2.1 Terminal connection diagram (when source logic is selected) z 3-phase 400V power input Motor 3-phase AC power supply Earth(Ground) 24VDC power output and contact input common Jumper Note 4 Remove this jumper when using the optional power-factor improving DC reactor. - Page 27 INSTALLATION AND WIRING z Single-phase 200V power input Motor Power supply Earth(Ground) Note: 1. To ensure safety, connect the power input to the inverter via a magnetic contactor and earth leakage circuit breaker or no-fuse breaker, and use the magnetic contactor to switch power on-off. 2.

- Page 28 INSTALLATION AND WIRING (2) Description of the control circuit terminals Type Symbol Terminal Name Description Forward Turn on the STF signal to start forward When the STF rotation start rotation and turn it off to stop. and STR signals are turned on simultaneously, Reverse Turn on the STR signal to start reverse...

- Page 29 INSTALLATION AND WIRING Type Symbol Terminal Name Description Change-over contact output indicating that the output has been stopped by the inverter protective function activated. 230VAC 0.3A, A, B, C Alarm output 30VDC 0.3A. Alarm: discontinuity across B-C (continuity across A-C), normal: continuity Output across B-C (discontinuity across A-C).

-

Page 30: Wiring Of The Main Circuit

INSTALLATION AND WIRING 2.2.2 Wiring of the Main Circuit (1) Wiring instructions 1) It is recommended to use insulation-sleeved solderless terminals for power supply and motor wiring. 2) Power must not be applied to the output terminals (U, V, W) of the inverter. Otherwise the inverter will be damaged. - Page 31 INSTALLATION AND WIRING 6) Connect only the recommended optional brake resistor between the + - PR. These terminals must not be shorted. 7) Electromagnetic wave interference The input/output (main circuit) of the inverter includes harmonic components, which may interfere with the communication devices (such as AM radios) used near the inverter.

- Page 32 INSTALLATION AND WIRING (2) Terminal block layout FR-E540-0.4K to 7.5K-EC FR-E520S-0.4K to 2.2K-EC − − Screw size (M4) Screw size (M4) Screw size (M4) Screw size (M4) (3) Cables, crimping terminals, etc. The following table lists the cables and crimping terminals used with the inputs (L ) and outputs (U, V, W) of the inverter and the torques for tightening the screws: 1) FR-E540-0.4K to 7.5K-EC PVC Insulated...

- Page 33 INSTALLATION AND WIRING 2) FR-E520S-0.4K to 2.2K-EC PVC Insulated Tight- Crimping Cables Applicable Terminal Cables ening Inverter Screw Terminals Torque Type Size N⋅m U, V, W U, V, W U, V, W U, V, W FR-E520S- 2-3.5 2-3.5 0.4K-EC FR-E520S- 0.75K-EC FR-E520S- 1.5K-EC...

- Page 34 INSTALLATION AND WIRING (4) Connection of the power supply and motor z Three-phase power input Three-phase power supply 400V Motor Earth(Ground) Earth(Ground) terminal No-fuse breaker Earth(Ground) The power supply cables must be connected Connect the motor to U, V, W. In the above to L .

-

Page 35: Wiring Of The Control Circuit

INSTALLATION AND WIRING 2.2.3 Wiring of the control circuit (1) Wiring instructions 1) Terminals PC, SE and 5 (and SD when sink logic is selected) are common to the I/O signals. These common terminals must not be earthed to the ground. 2) Use shielded or twisted cables for connection to the control circuit terminals and run them away from the main and power circuits (including the 200V relay sequence circuit). - Page 36 INSTALLATION AND WIRING 2) When using bar terminals and solid wires for wiring, their diameters should be 0.9mm maximum. If they are larger, the threads may be damaged during tightening. 3) Loosen the terminal screw and insert the cable into the terminal. 4) Tighten the screw to the specified torque.

- Page 37 INSTALLATION AND WIRING 2) Source logic type • In this logic, a signal switches on when a current flows into the corresponding signal input terminal. Terminal PC is common to the contact input signals. Terminal SE common to the open collector output signals. •...

- Page 38 INSTALLATION AND WIRING • When using an external power supply for transistor output, use terminal PC as a common to prevent misoperation caused by leakage current. (Do not connect terminal SD of the inverter with terminal 0V of the external power supply.

-

Page 39: Connection To The Pu Connector

INSTALLATION AND WIRING 2.2.4 Connection to the PU connector (1) When connecting the control panel or parameter unit using a cable Use the option FR-CB2… or the following connector and commercially available cable: <Connection cable> y Connector : RJ45 connector Example: 5-554720-3, Nippon AMP y Cable : Cable conforming to EIA568 (e.g. - Page 40 Example: 5-554720-3, Nippon AMP Co., Ltd. 2. Cable : Cable conforming to EIA568 (such as 10BASE-T cable) Example: SGLPEV 0.5mm × 4P, Mitsubishi Cable Industries, Ltd. 3.*Commercially available converter examples Model: FA-T-RS40 Converter Nagoya Sales Office, Mitsubishi Electric Engineering Co., Ltd.

- Page 41 INSTALLATION AND WIRING <Wiring methods> 1) Wiring of one RS-485 computer and one inverter Computer Side Terminals Cable connection and signal direction Inverter PU connector Signal name Description 10 BASE-T Cable Receive data Receive data Send data Send data Request to send Request to send (Note 1) Clear to send...

-

Page 42: Connection Of Stand-Alone Option Units

INSTALLATION AND WIRING 2.2.5 Connection of stand-alone option units The inverter accepts a variety of stand-alone option units as required. Incorrect connection will cause inverter damage or an accident. Connect and operate the option unit carefully in accordance with the corresponding option unit manual. (1) Connection of the dedicated external brake resistor (option) Connect a brake resistor across terminals + and PR. - Page 43 INSTALLATION AND WIRING (3) Connection of the FR-HC high power factor converter (option unit) (In the case of single-phase power input, the FR-HC cannot be connected.) When connecting the high power factor converter (FR-HC) to suppress power harmonics, wire as shown below. Wrong connection will damage the high power factor converter and inverter.

-

Page 44: Design Information

INSTALLATION AND WIRING 2.2.6 Design information 1) Provide electrical and mechanical interlocks for MC1 and MC2 which are used for commercial power supply-inverter switch-over. When there is a commercial power supply-inverter switch-over circuit as shown below, the inverter will be damaged by leakage current from the power supply due to arcs generated at the time of switch-over or chattering caused by a sequence error. -

Page 45: Other Wiring

2.3 Other Wiring INSTALLATION AND WIRING 2.3 Other wiring 2.3.1 Power supply harmonics Power supply harmonics may be generated from the converter section of the inverter, affecting the power supply equipment, power capacitor, etc. Power supply harmonics are different in generation source, frequency band and transmission path from radio frequency (RF) noise and leakage currents. -

Page 46: Inverter-Generated Noise And Reduction Techniques

INSTALLATION AND WIRING 2.3.2 Inverter-generated noise and reduction techniques Some noises enter the inverter causing it to incorrectly operate, and others are radiated by the inverter causing misoperation of peripheral devices. Though the inverter is designed to be insusceptible to noise, it handles low-level signals, so it requires the following basic measures to be taken. - Page 47 INSTALLATION AND WIRING 3) Measures against noises which are radiated by the inverter causing misoperation of peripheral devices. Inverter-generated noises are largely classified into those radiated by the cables connected to the inverter and inverter main circuit (I/O), those electromagnetically and electrostatically inducted to the signal cables of the peripheral devices close to the main circuit power supply, and those transmitted through the power supply cables.

- Page 48 INSTALLATION AND WIRING Noise Path Measures When devices which handle low-level signals and are susceptible to misoperation due to noise (such as instruments, receivers and sensors) are installed near the inverter and their signal cables are contained in the same panel as the inverter or are run near the inverter, the devices may be misoperated by air-propagated noise and the following measures must be taken: (1) Install easily affected devices as far away as possible from the...

- Page 49 INSTALLATION AND WIRING z Data line filter Noise entry can be prevented by providing a data line filter for the detector or other cable. z Example of counter measures against noise FR-BLF Install filter Control box Reduce carrier frequency. FR-BLF FR-BSF01 Install filter FR-BSF01...

-

Page 50: Leakage Currents And Countermeasures

INSTALLATION AND WIRING 2.3.3 Leakage currents and countermeasures Due to the static capacitance existing in the inverter I/O wiring and motor, leakage currents flow through them. Since their values depend on the static capacitance, carrier frequency, etc., take the following measures. (1) To-earth (ground) leakage currents Leakage currents may flow not only into the inverter's own line but also into the other lines through the earth (ground) cable, etc. -

Page 51: Inverter-Driven 400V Class Motor

INSTALLATION AND WIRING z Countermeasures y Use the electronic overcurrent protection of the inverter. y Decrease the carrier frequency. Note that motor noise increases. Selection of Soft-PWM will make it unoffending. To ensure that the motor is protected against line-to-line leakage currents, it is recommended to use a temperature sensor to directly detect motor temperature. -

Page 52: Peripheral Devices

Breaker (NV) (MC) Inverter Type Output Capacity With power factor (kW) Standard (kVA) improving reactor FR-E540-0.4K-EC Type NF30, NV30 5A Type NF30, NV30 5A S-N10 FR-E540-0.75K-EC 0.75 Type NF30, NV30 5A Type NF30, NV30 5A S-N10 FR-E540-1.5K-EC Type NF30, NV30 10A... - Page 53 Also the earth leakage circuit breaker used should be our product durable against harmonics/surges (such as the Progressive Super Series). z Power factor improving reactor Power Factor Improving Power Factor Improving Inverter Model AC Reactor DC Reactor FR-E540-0.4K-EC FR-BAL-H0.4K FR-BEL-H0.4K FR-E540-0.75K-EC FR-BAL-H0.75K FR-BEL-H0.75K FR-E540-1.5K-EC FR-BAL-H1.5K FR-BEL-H1.5K...

- Page 54 INSTALLATION AND WIRING (2) Selecting the rated sensitivity current for the earth leakage circuit breaker When using the earth leakage circuit breaker with the inverter circuit, select its rated sensitivity current as follows, independently of the PWM carrier frequency: xample of leakage current per 1km in Leakage current example of 3-phase induction motor during commercial able path during commercial power...

- Page 55 INSTALLATION AND WIRING Progressive Super Series Conventional NV (Type SP, CF, SF,CP) (Type CA, CS, SS) 33 × Leakage current (Ig1) (mA) = 0.17 1000m Leakage current (Ign) (mA) 0 (without noise filter) 33 × Leakage current (Ig2) (mA) = 2.31 1000m Motor leakage 0.18...

-

Page 56: Instructions For Compliance With U.s. And Canadian Electrical Codes

Rated Rated Rated Rated Applicable Inverter Applicable Inverter Voltage Current( Voltage Current( Type Type FR-E540-0.4K-EC FR-E520S-0.4K-EC FR-E540-0.75K-EC FR-E520S-0.75K-EC FR-E540-1.5K-EC FR-E520S-1.5K-EC FR-E540-2.2K-EC FR-E520S-2.2K-EC FR-E540-3.7K-EC FR-E540-5.5K-EC FR-E540-7.5K-EC (3) Short circuit ratings Suitable For Use In A Circuit Capable Of Delivering Not More Than 5 kA rms... -

Page 57: Instructions For Compliance With The European Standards

INSTALLATION AND WIRING 2.3.7 Instructions for compliance with the European standards (The products conforming to the Low Voltage Directive carry the CE mark.) (1) EMC Directive 1) Our view of transistorized inverters for the EMC Directive A transistorized inverter is a component designed for installation in a control box and for use with the other equipment to control the equipment/device. - Page 58 INSTALLATION AND WIRING (2) Low Voltage Directive 1) Our view of transistorized inverters for the Low Voltage Directive Transistorized inverters are covered by the Low Voltage Directive. 2) Compliance We have self-confirmed our inverters as products compliant to the Low Voltage Directive and place the CE mark on the inverters.

- Page 59 INSTALLATION AND WIRING * The terminals indicated as the input and output terminals for control circuit on page 13 are isolated safely from the main circuit. Environment During During operation In storage transportation Ambient -10°C to +50°C -20°C to +65°C -20°C to +65°C Temperature Ambient Humidity...

-

Page 60: Operation/Control

CHAPTER 3 OPERATION/CONTROL This chapter provides the basic "operation/control" for use of this product. Always read this chapter before using the equipment. 3.1 Pre-Operation Information ........47 C hapter 1 3.2 About the Control Panel..........50 3.3 Operation..............56 C hapter 2 C hapter 3 C hapter 4 C hapter 5... -

Page 61: Pre-Operation Information

3.1 Pre-Operation Information 3 OPERATION/CONTROL 3.1 Pre-Operation Information 3.1.1 Types of operation modes The inverter can be operated in any of "PU operation mode", "external operation mode", "combined operation mode" and "communication operation mode". Prepare required instruments and parts according to the operation mode. For the way of changing the operation mode, refer to page 53. - Page 62 (3) Combined operation mode 1 (Pr. 79 "operation mode selection" = 3) The start signal is an external signal. The frequency setting signal is made setting using the optional control panel or parameter unit. Preparation y Start signal ..... Switch, relay, etc. y Operation unit..

-

Page 63: Power On

(5) Communication operation mode (Pr. 79 "operation mode selection" = 0 or 1) Communication operation can be performed by connecting a personal computer and the PU connector with the RS-485 communication cable. Preparation y Connection cable ......Connector: RJ45 connector Cable: Cable conforming to EIA568 (e.g. -

Page 64: About The Control Panel

3.2 About the Control Panel 3.2 About the Control Panel With the optional control panel (FR-PA02- ), you can run the inverter, set the frequency, monitor the operation command display, set parameters, and display an error. 3.2.1 Names and functions of the control panel (FR-PA02- Cover opened Unit indication Display... -

Page 65: Control Panel Mode Is Changed By Pressing The

3.2.2 Control panel mode is changed by pressing the MODE Monitoring mode Frequency setting Parameter setting mode (Note) mode MODE MODE MODE MODE MODE STOP STOP STOP RESET RESET RESET MODE Help mode Operation mode MODE MODE MODE MODE STOP STOP RESET RESET... -

Page 66: Parameter Setting Method

3.2.4 Frequency setting Set the frequency value used for operation performed under the operation command given by the key ( key) in the PU operation mode. This mode is displayed only in PU operation. To frequency monitoring Frequency setting mode Set frequency changing Set frequency MODE... - Page 67 (1) Example: To change the Pr. 79 "operation mode selection" setting from "2" (external operation mode) to "1" (PU operation mode) (For details of Pr. 79, refer to page 106.) Press the key, to choose the MODE parameter setting mode. Parameter setting mode Most significant Least significant...

-

Page 68: Operation Mode

3.2.6 Operation mode The operation mode change method which is shown below is only allowed when Pr. 79 "operation mode selection" is "0". PU operation PU jog operation External operation MODE STOP MODE MODE RESET MODE To 3.2.7 Help mode Note: If the operation mode cannot be changed, refer to page 168. - Page 69 (1) Alarm history Four past alarms can be displayed with the key. ("." is appended to the most recent alarm.) When no alarm exists, E._ _0 is displayed. Most recent alarm When alarm occurs Frequency Current PU EXT Voltage Energization time PU EXT PU EXT (2) Alarm history clear...

-

Page 70: Operation

3.3 Operation 3.3 Operation 3.3.1 Pre-operation checks Before starting operation, check the following: z Safety Perform test operation after making sure that safety is ensured if the machine should become out of control. z Machine Make sure that the machine is free of damage. z Parameters Set the parameter values to match the operating machine (system) environment. -

Page 71: External Operation Mode (Operation Using The External Frequency Setting Potentiometer And External Start Signal)

3.3.2 External operation mode (Operation using the external frequency setting potentiometer and external start signal) (1) Operation at 50Hz Operation command: Externally connected start signal Frequency setting: Externally connected frequency setting potentiometer Step Description Image Power on → Operation mode check With the factory setting, the external operation mode is selected and the [EXT] indication is lit when power is switched on. -

Page 72: Pu Operation Mode (Operation Using The Control Panel)

3.3.3 PU operation mode (Operation using the control panel) (1) Using the control panel (FR-PA02- ) for operation at 50Hz with digital frequency setting Operation command: key or control panel (FR-PA02- Frequency setting: Related parameters: Pr. 79 "operation mode selection" By repeating step 2 below during motor run, speed can be varied. -

Page 73: Combined Operation Mode 1 (Operation Using Both External Start Signal And Control Panel)

3.3.4 Combined operation mode 1 (Operation using both external start signal and control panel) When the start signal is provided externally (switch etc.) and the running frequency is set from the control panel (Pr. 79 = 3). The external frequency setting signal and PU's forward rotation, reverse rotation and STOP keys are not accepted. -

Page 74: Combined Operation Mode 2

3.3.5 Combined operation mode 2 When the running frequency is set from a potentiometer connected across terminals 2-5 (frequency setting potentiometer) and the start signal is provided by the key or ). (Pr.79 = 4) key of the control panel (FR-PA02- Operation command: key (or key) of the control panel... - Page 75 C H A P T E R 4 CHAPTER 4 P A R A M E T E R S PARAMETERS This chapter explains the "parameters" of this product. With the factory settings, the inverter is designed to perform simple variable-speed operation. Set necessary parameter values according to the load and operating specifications.

-

Page 76: Parameters

4.1 Parameter List PARAMETERS 4 PARAMETERS 4.1 Parameter List 4.1.1 Parameter list Para- Minimum Custo- Func- Setting Factory Refer meter Name Setting tion Range Setting Number Increments Setting 6%/4% Torque boost (Note 1) 0 to 30% 0.1% (Note 8) 0.01Hz Maximum frequency 0 to 120Hz 120Hz... - Page 77 PARAMETERS Para- Minimum Custo- Func- Setting Factory Refer meter Name Setting tion Range Setting Number Increments Setting 0 to 400Hz, 0.01Hz Multi-speed setting (speed 7) 9999 9999 (Note 3) Acceleration/deceleration 0, 1, 2 pattern Regenerative function 0, 1 selection 0 to 400Hz, 0.01Hz Frequency jump 1A 9999...

- Page 78 PARAMETERS Para- Minimum Custo- Func- Setting Factory Refer meter Name Setting tion Range Setting Number Increments Setting Shortest acceleration/ 0, 1, 2, 11, deceleration mode Reference I for intelligent 0 to 500A, 0.01A 9999 mode 9999 Ref. I for intelligent mode 0 to 200%, 9999 accel...

- Page 79 PARAMETERS Para- Minimum Custo- Func- Setting Factory Refer meter Name Setting tion Range Setting Number Increments Setting Station number 0 to 31 Communication speed 48, 96, 192 0, 1 (data length 8) Stop bit length 10, 11 (data length 7) Parity check presence/ 0, 1, 2 absence...

- Page 80 PARAMETERS Para- Minimum Custo- Func- Setting Factory Refer meter Name Setting tion Range Setting Number Increments Setting User group read selection 0, 1, 10, 11 Parameters set by manufacturer. Do not set. Actual operation hour meter clear User group 1 registration 0 to 999 0 to User group 1 deletion...

- Page 81 PARAMETERS Para- Minimum Custo- Func- Setting Factory Refer meter Name Setting tion Range Setting Number Increments Setting 0 to 100 s, 1000 to Stop selection 9999 1100 s, 8888, 9999 AM terminal calibration Frequency setting voltage 0 to 0 to 0.01Hz 0V 0Hz...

-

Page 82: List Of Parameters Classified By Purpose Of Use

PARAMETERS 4.1.2 List of Parameters Classified by Purpose of Use Set the parameters according to the operating conditions. The following list indicates purpose of use and corresponding parameters. Parameter Numbers Purpose of Use Parameter numbers which must be set Operation mode selection Pr. - Page 83 PARAMETERS Parameter Numbers Purpose of Use Parameter numbers which must be set Frequency meter calibration Pr. 55, Pr. 56, Pr. 158, Pr. 901 Monitor display on control panel (FR-PA02- ) or parameter unit Pr. 55, Pr. 56, Pr. 158, Pr. 901 (FR-PU04) Display of speed, etc.

-

Page 84: Parameters Recommended To Be Set By The User

PARAMETERS 4.1.3 Parameters recommended to be set by the user We recommend the following parameters to be set by the user. Set them according to the operation specifications, load, etc. Parameter Name Application Number Maximum frequency Used to set the maximum and minimum output Minimum frequency frequencies. -

Page 85: Parameter Function Details

4.2 Parameter Function Details PARAMETERS 4.2 Parameter Function Details 4.2.1 Torque boost (Pr. 0, Pr. 46) Pr. 0 "torque boost" Related parameters Pr. 3 "base frequency" Pr. 46 "second torque boost" Pr. 19 "base frequency voltage" Pr. 71 "applied motor" Pr. -

Page 86: Output Frequency Range (Pr. 1, Pr. 2, Pr. 18)

PARAMETERS 4.2.2 Output frequency range (Pr. 1, Pr. 2, Pr. 18) Related parameters Pr. 1 "maximum frequency" Pr. 13 "starting frequency" Pr. 38 "frequency at 5V (10V) input" Pr. 2 "minimum frequency" Pr. 39 "frequency at 20m A input" Pr. 79 "operation m ode selection" Pr. -

Page 87: Base Frequency, Base Frequency Voltage (Pr. 3, Pr. 19, Pr. 47)

PARAMETERS Base frequency, base frequency voltage (Pr. 3, Pr. 19, Pr. 47) 4.2.3 Base frequency, base frequency voltage (Pr. 3, Pr. 19, Pr. 47) Related parameters Pr. 3 "base frequency" Pr. 71 "applied motor" Pr. 80 "motor capacity" Pr. 19 "base frequency voltage" Pr. -

Page 88: Multi-Speed Operation

PARAMETERS Multi-speed operation (Pr. 4 to Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239) 4.2.4 Multi-speed operation (Pr. 4, Pr. 5, Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239) Related parameters Pr. 4 "multi-speed setting (high speed)" Pr. -

Page 89: Acceleration/Deceleration Time (Pr. 7, Pr. 8, Pr. 20, Pr. 21, Pr. 44, Pr. 45)

PARAMETERS Note: 1. The multi-speed settings override the main speeds (across terminals 2-5, 4-5). 2. The multi-speeds can also be set in the PU or external operation mode. 3. For 3-speed setting, if two or three speeds are simultaneously selected, priority is given to the frequency setting of the lower signal. - Page 90 PARAMETERS <Setting> y Use Pr. 21 to set the acceleration/deceleration time and minimum setting increments: Set value "0" (factory setting) ..0 to 3600 s (minimum setting increments: 0.1 s) Set value "1"......0 to 360 s (minimum setting increments: 0.01 s) y Use Pr.

-

Page 91: Electronic Overcurrent Protection (Pr. 9, Pr. 48)

PARAMETERS 4.2.6 Electronic overcurrent protection (Pr. 9, Pr. 48) Related parameter Pr. 9 "electronic thermal O/L relay" Pr. 71 "applied motor" Pr. 180 to Pr. 183 Pr. 48 "second electronic overcurrent "input terminal function protection" selection" Set the current of the electronic overcurrent protection to protect the motor from overheat. -

Page 92: Dc Injection Brake (Pr. 10 To Pr. 12)

PARAMETERS DC dynamic brake (Pr. 10, Pr. 11, Pr. 12) 4.2.7 DC injection brake (Pr. 10 to Pr. 12) Pr. 10 "DC injection brake operation frequency" Pr. 11 "DC injection brake operation time" Pr. 12 "DC injection brake voltage" By setting the DC injection brake voltage (torque), operation time and operation starting frequency, the stopping accuracy of positioning operation, etc. -

Page 93: Starting Frequency (Pr. 13)

PARAMETERS 4.2.8 Starting frequency (Pr. 13) Related parameter Pr. 13 "starting frequency" Pr. 2 "minimum frequency" You can set the starting frequency between 0 and 60Hz. y Set the starting frequency at which the start signal is switched on. Parameter Factory Output frequency Setting Range... -

Page 94: Load Pattern Selection (Pr. 14)

PARAMETERS 4.2.9 Load pattern selection (Pr. 14) Load pattern selection (Pr. 14) Related parameter Pr. 14 "load pattern selection" Pr. 0 "torque boost" Pr.46 "second torque boost" Pr. 80 "motor capacity" Pr.180 to Pr.183 (input terminal function selection) You can select the optimum output characteristic (V/F characteristic) for the application and load characteristics. -

Page 95: Jog Operation (Pr. 15, Pr. 16)

PARAMETERS Jog operation (Pr. 15, Pr. 16) 4.2.10 Jog operation (Pr. 15, Pr. 16) Related parameters Pr. 15 "jog frequency" Pr. 20 "acceleration/deceleration reference frequency" Pr. 16 "jog acceleration/deceleration Pr. 21 "acceleration/deceleration time increments" time" Jog operation can be started and stopped by selecting the jog mode from the control panel and pressing and releasing the key ( key). -

Page 96: Stall Prevention (Pr. 22, Pr. 23, Pr. 66)

PARAMETERS Stall prevention (Pr. 22, Pr. 23, Pr. 66) 4.2.11 Stall prevention (Pr. 22, Pr. 23, Pr. 66) Related parameters Pr. 22 "stall prevention operation level" Pr. 9 "electronic thermal O/L relay" Pr. 48 "second electronic Pr. 23 "stall prevention operation level overcurrent protection"... - Page 97 PARAMETERS <Setting> y In Pr. 22, set the stall prevention operation level. Normally set it to 150% (factory setting). Set "0" in Pr. 22 to disable the stall prevention operation. y To reduce the stall prevention operation level in the high-frequency range, set the reduction starting frequency in Pr.

-

Page 98: Acceleration/Deceleration Pattern (Pr. 29)

PARAMETERS Acceleration/deceleration pattern (Pr. 29) 4.2.12 Acceleration/deceleration pattern (Pr. 29) Related parameters Pr. 29 "acceleration/deceleration pattern" Pr. 3 "base frequency" Pr. 7 "acceleration time" Pr. 8 "deceleration time" Pr. 20 "acceleration/deceleration reference frequency" Pr. 44 "second Set the acceleration/deceleration pattern. acceleration/deceleration time"... -

Page 99: Regenerative Brake Duty (Pr. 30, Pr. 70)

PARAMETERS Regenerative brake duty (Pr. 30, Pr. 70) 4.2.13 Regenerative brake duty (Pr. 30, Pr. 70) Pr. 30 "regenerative function selection" Pr. 70 "special regenerative brake duty" y When making frequent starts/stops, use the optional "brake resistor" to increase the regenerative brake duty. -

Page 100: Frequency Jump (Pr. 31 To Pr. 36)

PARAMETERS Frequency jump (Pr. 31 to Pr. 36) 4.2.14 Frequency jump (Pr. 31 to Pr. 36) Pr. 31 "frequency jump 1A" Pr. 32 "frequency jump 1B" Pr. 33 "frequency jump 2A" Pr. 34 "frequency jump 2B" Pr. 35 "frequency jump 3A" Pr. -

Page 101: Speed Display (Pr. 37)

PARAMETERS Speed display (Pr. 37) 4.2.15 Speed display (Pr. 37) Related parameter Pr. 37 "speed display" Pr. 52 "control panel/PU main display data selection" The unit of the output frequency display of the control panel (FR-PA02- ) and PU (FR-PU04) can be changed from the frequency to the motor speed or machine speed. Parameter Factory Setting Range... -

Page 102: Frequency At 5V (10V) Input (Pr. 38)

PARAMETERS Frequency at 5V (10V) input (Pr. 38) 4.2.16 Frequency at 5V (10V) input (Pr. 38) Related parameters Pr. 38 "frequency at 5V (10V) input" Pr. 73 "0-5V/0-10V selection" Pr. 79 "operation m ode selection" Pr. 902 "frequency setting voltage bias" Pr. -

Page 103: Up-To-Frequency Sensitivity (Pr. 41)

PARAMETERS Up-to-frequency sensitivity (Pr. 41) 4.2.18 Up-to-frequency sensitivity (Pr. 41) Related parameters Pr. 41 "up-to-frequency sensitivity" Pr. 190 "RUN term inal function selection" Pr. 191 "FU term inal function selection" Pr. 192 "A, B, C terminal function selection" The ON range of the up-to-frequency signal (SU) output when the output frequency reaches the running frequency can be adjusted between 0 and ±100% of the running frequency. -

Page 104: Output Frequency Detection (Pr. 42, Pr. 43)

PARAMETERS 4.2.19 Output frequency detection (Pr. 42, Pr. 43) Output frequency detection (Pr. 42, Pr. 43) Related parameters Pr. 42 "output frequency detection" Pr. 190 "RUN term inal function selection" Pr. 191 "FU term inal function selection" Pr. 43 "output frequency detection for Pr. -

Page 105: Monitor Display (Pr. 52, Pr. 158)

PARAMETERS Pr. 44, Pr. 45 ÎRefer to Pr. 7. Pr. 46 ÎRefer to Pr. 0. Pr. 47 ÎRefer to Pr. 3. Pr. 48 ÎRefer to Pr. 9 4.2.20 Monitor display (Pr. 52, Pr. 158) Related parameters Pr. 52 "control panel/PU main display Pr. - Page 106 PARAMETERS <Setting> Set Pr. 52 and Pr. 158 in accordance with the following table: Parameter Setting Pr. 52 Pr. 158 Full-Scale Value of Signal Type Unit AM Level Meter Control PU main panel LED monitor terminal Output 0/100 0/100 Pr. 55 frequency Output current 0/100...

-

Page 107: Monitoring Reference (Pr. 55, Pr. 56)

PARAMETERS Monitoring reference (Pr. 55, Pr. 56) 4.2.21 Monitoring reference (Pr. 55, Pr. 56) Related parameters Pr. 55 "frequency monitoring reference" Pr. 158 "AM terminal function selection" Pr. 56 "current monitoring reference" Pr. 901 "AM terminal calibration" Set the frequency or current which is referenced when the output frequency or output current is selected for the AM terminal. -

Page 108: Automatic Restart After Instantaneous Power Failure (Pr. 57, Pr. 58)

PARAMETERS Automatic restart after instantaneous power failure (Pr. 57, Pr. 58) 4.2.22 Automatic restart after instantaneous power failure (Pr. 57, Pr. 58) P r. 57 "restart coasting tim e" P r. 58 "restart cushion tim e" y You can restart the inverter without stopping the motor (with the motor coasting) when power is restored after an instantaneous power failure. -

Page 109: Remote Setting Function Selection (Pr. 59)

PARAMETERS Remote setting function selection (Pr. 59) 4.2.23 Remote setting function selection (Pr. 59) Related parameters Pr. 59 "remote setting function selection" Pr. 1 "maximum frequency" Pr. 7 "acceleration time" If the operator panel is located away from the Pr. 8 "deceleration time" control box, you can use contact signals to Pr. -

Page 110: Shortest Acceleration/Deceleration Mode (Pr. 60 To Pr. 63)

PARAMETERS Note: 1. The frequency can be varied by RH (acceleration) and RM (deceleration) between 0 and the maximum frequency (Pr. 1 or Pr. 18 setting). 2. When the acceleration or deceleration signal switches on, the set frequency varies according to the slope set in Pr. 44 or Pr. 45. The output frequency acceleration/deceleration times are as set in Pr. - Page 111 PARAMETERS Acceleration/deceleration reference current (Pr. 61, Pr. 62, Pr. 63) < Setting> Automatically Pr. 60 Operation Description Mode Setting Parameters Ordinary operation mode Set to accelerate/decelerate the motor in the shortest time. The inverter makes acceleration/deceleration in the shortest time using its full capabilities.

-

Page 112: Retry Function (Pr. 65, Pr. 67 To Pr. 69)

PARAMETERS Retry function (Pr. 65, Pr. 67, Pr. 68, Pr. 69) 4.2.25 Retry function (Pr. 65, Pr. 67 to Pr. 69) Pr. 65 "retry selection" Pr. 67 "number of retries at alarm occurrence" Pr. 68 "retry waiting time" Pr. 69 "retry count display erasure" When any protective function (major fault) is activated and the inverter stops its output, the inverter itself resets automatically and performs retries. - Page 113 PARAMETERS Use Pr. 67 to set the number of retries at alarm occurrence. Pr. 67 Setting Number of Retries Alarm Signal Output Retry is not made. 1 to 10 1 to 10 times Not output. 101 to 110 1 to 10 times Output.

-

Page 114: Applied Motor (Pr. 71)

PARAMETERS Applied motor (Pr. 71) 4.2.26 Applied motor (Pr. 71) Related parameters Pr. 71 "applied motor" Pr. 0 "torque boost" Pr. 12 "DC injection brake voltage" Pr. 19 "base frequency voltage" Pr. 80 "motor capacity" Pr. 96 "auto-tuning setting/status" Set the motor used. y When using the Mitsubishi constant-torque motor, set "1"... -

Page 115: Pwm Carrier Frequency (Pr. 72, Pr. 240)

PARAMETERS PWM carrier frequency (Pr. 72, Pr. 240) 4.2.27 PWM carrier frequency (Pr. 72, Pr. 240) Pr. 72 "PWM frequency selection" Pr. 240 "Soft-PWM setting" You can change the motor tone. y By parameter setting, you can select Soft-PWM control which changes the motor tone. -

Page 116: Voltage Input (Pr. 73)

PARAMETERS Voltage input (Pr. 73) 4.2.28 Voltage input (Pr. 73) Related parameters Pr. 73 "0-5V/0-10V selection" Pr. 22 "stall prevention operation level" Pr. 38 "frequency at 5V (10V) input" y You can change the input (terminal 2) specifications in response to the frequency setting voltage signal. -

Page 117: Input Filter Time Constant (Pr. 74)

PARAMETERS Input filter time constant (Pr. 74) 4.2.29 Input filter time constant (Pr. 74) Pr. 74 "filter time constant" You can set the input section's internal filter constant for an external voltage or current frequency setting signal. y Effective for eliminating noise in the frequency setting circuit. y Increase the filter time constant if steady operation cannot be performed due to noise. - Page 118 PARAMETERS <Setting> Pr. 75 Reset Selection PU Disconnection Detection PU Stop Selection Setting Reset input normally enabled. Pressing the If the PU is disconnected, Reset input enabled only when the STOP operation will be continued. RESET protective function is activated. decelerates the Reset input normally enabled.

-

Page 119: Parameter Write Inhibit Selection (Pr. 77)

PARAMETERS Note: 1. By entering the reset signal (RES) during operation, the inverter shuts off output while it is reset, the data of the electronic overcurrent protection and regenerative brake duty are reset, and the motor coasts. 2. The PU disconnection detection function judges that the PU is disconnected when it is removed from the inverter for more than 1 second. -

Page 120: Reverse Rotation Prevention Selection (Pr. 78)

PARAMETERS <Setting> Pr. 77 Function Setting Parameter values may only be written during a stop in the PU operation mode. (Note 1) Write disabled. Values of Pr. 75, Pr. 77 and Pr. 79 "operation mode selection" may be written. Write enabled even during operation. Note: 1. -

Page 121: Operation Mode Selection (Pr. 79)

PARAMETERS Operation mode selection (Pr. 79) 4.2.33 Operation mode selection (Pr. 79) Related parameters Pr. 79 "operation mode selection" Pr. 4 to Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239 "multi-speed operation" Used to select the operation mode of the inverter. Pr. - Page 122 PARAMETERS Note: Either "3" or "4" may be set to select the PU/external combined operation. These settings differ in starting method. (1) Switch-over mode During operation, you can change the current operation mode to another operation mode. Operation Mode Switching Switching Control/Operating Status External operation to PU 1) Operate the control panel keys to select the PU operation...

- Page 123 PARAMETERS 2) Function MRS Signal Function/Operation Output stopped during external operation. Operation mode can be switched to PU operation mode. Parameter values can be rewritten in PU operation mode. PU operation allowed. Forcibly switched to external operation mode. External operation allowed. Switching to PU operation mode inhibited.

- Page 124 PARAMETERS (3) Operation mode switching by external signal 1) Preparation Set "8" (switching to other than external operation mode) in Pr. 79. Use any of Pr. 180 to Pr. 183 (input terminal function selection) to set the terminal used for X16 signal input. Refer to page 142 for Pr.

-

Page 125: General-Purpose Magnetic Flux Vector Control Selection (Pr. 80)

PARAMETERS 4.2.34 General-purpose magnetic flux vector control selection (Pr. 80) Related parameters Pr. 80 "motor capacity" Pr. 71 "applied motor" Pr. 83 "rated motor voltage" You can set the general-purpose magnetic flux Pr. 84 "rated motor frequency" vector control. Pr. 96 "auto-tuning setting/status" z General-purpose magnetic flux vector control Provides large starting torque and sufficient low-speed torque. -

Page 126: Offline Auto Tuning Function (Pr. 82 To Pr. 84, Pr. 90, Pr. 96)

PARAMETERS Offline auto tuning function (Pr. 82 to Pr. 84, Pr. 90, Pr. 96) 4.2.35 Offline auto tuning function (Pr. 82 to Pr. 84, Pr. 90, Pr. 96) Related parameters Pr. 82 "motor exciting current" Pr. 7 "acceleration time" Pr. 9 "electronic thermal O/L Pr. - Page 127 PARAMETERS <Operating conditions> y The motor is connected. y The motor capacity is equal to or one rank lower than the inverter capacity. y Special motors such as high-slip motors and high-speed motors cannot be tuned. y The motor may move slightly. Therefore, fix the motor securely with a mechanical brake, or before tuning, make sure that there will be no problem in safety if the motor runs.

- Page 128 PARAMETERS „ Parameter details Parameter Setting Description Number 0 to 500A Set the rated motor current (A). 0, 100 Thermal characteristics suitable for standard motor Thermal characteristics suitable for Mitsubishi's constant- 1, 101 torque motor 3, 103 Standard motor 13, 113 Constant-torque motor Select "offline auto tuning setting"...

- Page 129 PARAMETERS (3) Monitoring the offline tuning status When the parameter unit (FR-PU04) is used, the Pr. 96 value is displayed during tuning on the main monitor as shown below. When the control panel is used, the same value as on the PU is only displayed: y Control panel (FR-PA02- ) display (For inverter trip)

- Page 130 PARAMETERS 4) Error display definitions Error Display Error Cause Remedy Inverter trip Make setting again. Increase Current limit (stall prevention) function was acceleration/deceleration time. activated. Set "1" in Pr. 156. Converter output voltage reached 75% of Check for fluctuation of power rated value.

- Page 131 PARAMETERS <Setting the motor constant as desired> z To set the motor constant without using the offline auto tuning data <Operating procedure> 1. Set "801" in Pr. 77. Only when the Pr. 80 setting is other than "9999", the parameter value of the motor constant (Pr. 90) can be displayed. Though the parameter values of other than the motor constant (Pr.

-

Page 132: Computer Link Operation (Pr. 117 To Pr. 124)

PARAMETERS 4.2.36 Computer link operation (Pr. 117 to Pr. 124) Pr. 117 "station number" Pr. 118 "communication speed" Pr. 119 "stop bit length" Pr. 120 "parity check presence/absence" Pr. 121 "number of communication retries" Pr. 122 "communication check time interval" Pr. - Page 133 PARAMETERS <Setting> Parameter Name Setting Description Number Station number specified for communication from the Station PU connector. 0 to 31 number Set the inverter station numbers when two or more inverters are connected to one personal computer. 4800 bps Communica- 9600 bps tion speed 19200 bps...

- Page 134 PARAMETERS *1. If a data error is detected and a retry must be made, execute retry operation with the user program. The inverter comes to an alarm stop if the number of consecutive retries exceeds the parameter setting. *2. On receipt of a data error occurrence, the inverter returns "reply data 3)" to the computer again.

- Page 135 PARAMETERS Note: 1. The inverter station numbers may be set between H00 and H1F (stations 0 and 31) in hexadecimal. 2. *3 indicates the control code. 3. *4 indicates the CR or LF code. When data is transmitted from the computer to the inverter, codes CR (carriage return) and LF (line feed) are automatically set at the end of a data group on some computers.

- Page 136 PARAMETERS 2) Inverter station number Specify the station number of the inverter which communicates with the computer. 3) Instruction code Specify the processing request, e.g. operation, monitoring, given by the computer to the inverter. Hence, the inverter can be run and monitored in various ways by specifying the instruction code as appropriate.

- Page 137 PARAMETERS Note: 1. When the data from the computer has an error, the inverter will not accept that data. 2. Any data communication, e.g. run command, monitoring, is started when the computer gives a communication request. Without the computer's command, the inverter does not return any data.

- Page 138 PARAMETERS <Setting items and set data> After completion of parameter settings, set the instruction codes and data then start communication from the computer to allow various types of operation control and monitoring. Number Instruction Item Description of Data Code Digits H0001: External operation Read H0002: Communication operation...

- Page 139 PARAMETERS Number Instruction Item Description of Data Code Digits b0: Inverter running (RUN) b1: Forward rotation 0 0 0 0 0 0 b2: Reverse rotation (For example 1) Inverter status b3: Up to frequency (SU) 2 digits [Example 1] H02 ... During forward b4: Overload (OL) monitor rotation...

- Page 140 PARAMETERS Number Instruction Item Description of Data Code Digits H00 to H6C and H80 to HEC parameter values are changed. Read H00: Pr. 0 to Pr. 96 values are accessible. Link H01: Pr. 117 to Pr. 158 and Pr. 901 to Pr. 905 parameter values are accessible.

- Page 141 PARAMETERS <Error Code List> The corresponding error code in the following list is displayed if an error is detected in any communication request data from the computer: Error Item Definition Inverter Operation Code number errors consecutively Computer NAK detected in communication request data error from the computer is greater than allowed number of retries.

- Page 142 PARAMETERS (5) Communication specifications for RS-485 communication Operation Mode Operation Communication Item Location Operation from PU External Operation Connector Run command (start) Enable Disable Enable Running frequency setting Enable (Combined operation mode) Computer user Monitoring Enable Enable program via PU connector Parameter write Enable (*2) Disable (*2)

-

Page 143: Pid Control (Pr. 128 To Pr. 134)

PARAMETERS PID control (Pr. 128 to Pr. 134) 4.2.37 PID control (Pr. 128 to Pr. 134) Related parameters Pr. 128 "PID action selection" Pr. 73 "0-5V/0-10V selection" Pr. 79 "operation mode selection" Pr. 129 "PID proportional band" Pr. 180 to Pr. 183 (input terminal function selection) Pr. - Page 144 PARAMETERS (2) PID action overview 1) PI action A combination of proportional control action (P) and integral control action (I) for providing a manipulated variable in response to deviation and changes with time. [Operation example for stepped changes of process value] Note: PI action is the sum of P and I Deviation Set point...

- Page 145 PARAMETERS 4) Reverse action Increases the manipulated variable (output frequency) if deviation X (set point - process value) is positive, and decreases the manipulated variable if deviation is negative. Deviation Set point [Heating] Cold fi up X>0 Set point X<0 fi down Process value Process value...

- Page 146 PARAMETERS (3) Wiring example y Pr. 190 = 14 y Pr. 191 = 15 y Pr. 192 = 16 Inverter Pump Motor Power supply Forward rotation Reverse rotation For 2-wire For 3-wire type type (Note 2) Detector Upper limit Lower limit −...

- Page 147 PARAMETERS (4) I/O signals Signal Terminal Used Function Description Set point input Enter the set point for PID control. Enter the 4 to 20mADC process value signal Process value input from the detector. Output to indicate that the process value Upper limit output signal exceeded the upper limit value.

- Page 148 PARAMETERS (5) Parameter setting Parameter Setting Name Description Number No PID action For heating, pressure control, action PID reverse action etc. selection For cooling, etc. PID forward action If the proportional band is narrow (parameter setting is small), the manipulated variable varies greatly with a slight change of the process value.

- Page 149 PARAMETERS (7) Calibration example (A detector of 4mA at 0°C and 20mA at 50°C is used to adjust the room temperature to 25°C under PID control. The set point is given to across inverter terminals 2-5 (0-5V).) START …… Determine the set point. Set the room temperature to 25°C Set "20"...

- Page 150 PARAMETERS <Set point input calibration> 1. Apply the input voltage of 0% set point setting (e.g. 0V) to across terminals 2-5. 2. Make calibration using Pr. 902. At this time, enter the frequency which should be output by the inverter at the deviation of 0% (e.g. 0Hz). 3.

-

Page 151: Output Current Detection Function (Pr. 150, Pr. 151)

PARAMETERS 4.2.38 Output current detection function (Pr. 150, Pr. 151) Related parameters Pr. 150 "output current detection level" Pr. 190 to Pr. 192 (output terminal function Pr. 151 "output current detection period" selection) y If the output current remains higher than the Pr. 150 setting during inverter operation for longer than the time set in Pr. -

Page 152: Zero Current Detection (Pr. 152, Pr. 153)

PARAMETERS Zero current detection (Pr. 152, Pr. 153) 4.2.39 Zero current detection (Pr. 152, Pr. 153) Related parameters Pr. 152 "zero current detection level" Pr. 190 to Pr. 192 (output terminal function selection) Pr. 153 "zero current detection period" When the inverter's output current falls to "0", torque will not be generated. This may cause a gravity drop when the inverter is used in vertical lift application. -

Page 153: Stall Prevention Function And Current Limit Function (Pr. 156)

PARAMETERS CAUTION The zero current detection level setting should not be too high, and the zero current detection time setting should not be too long. Otherwise, the detection signal may not be output when torque is not generated at a low output current. To prevent the machine and equipment from resulting in hazardous conditions by use of the zero current detection signal, install a safety backup such as an emergency brake. - Page 154 PARAMETERS <Setting> Refer to the following tables and set the parameter as required. Stall Prevention Stall Prevention OL Signal OL Signal Operation Voltage Operation Voltage Output Output : Activated Fast- Fast- : Activated : Not Response Response : Not activated Operation Operation activated...

-

Page 155: User Group Selection (Pr. 160, Pr. 173 To Pr. 176)

PARAMETERS 4.2.41 User group selection (Pr. 160, Pr. 173 to Pr. 176) Pr. 160 "user group read selection" Pr. 173 "user group 1 registration" Pr. 174 "user group 1 deletion" Pr. 175 "user group 2 registration" Pr. 176 "user group 2 deletion" Among all parameters, a total of 32 parameters can be registered to two different user groups. - Page 156 PARAMETERS (3) Set the required value in Pr. 160 to make the user group or groups valid or invalid. Pr. 160 Setting Description Previous parameters read User group 1's parameters read User group 2's parameters read User group 1 and 2 parameters read Note: 1.

-

Page 157: Actual Operation Hour Meter Clear (Pr. 171)

PARAMETERS Actual operation hour meter clear (Pr. 171) 4.2.42 Actual operation hour meter clear (Pr. 171) Related parameter Pr. 171 "actual operation hour meter Pr. 52 "control panel/PU main clear" display data selection" You can clear the actual operation hour of the monitoring function. Parameter Factory Setting Range... - Page 158 PARAMETERS <Setting> Refer to the following list and set the parameters. Signal Setting Function Related Parameters Name Pr. 4 to Pr. 6 Pr. 59 = 0 Low-speed operation command Pr. 24 to Pr. 27 Pr. 232 to Pr. 239 Pr. 59 = 1, 2 * Remote setting (setting clear) Pr.

-

Page 159: Output Terminal Function Selection (Pr. 190 To Pr. 192)

PARAMETERS Output terminal function selection (Pr. 190 to Pr. 192) 4.2.44 Output terminal function selection (Pr. 190 to Pr. 192) Pr. 190 "RUN terminal function selection" Pr. 191 "FU terminal function selection" Pr. 192 "A, B, C terminal function selection" You can change the functions of the open collector and contact output terminals. -

Page 160: Cooling Fan Operation Selection (Pr. 244)

PARAMETERS Pr. 232 to Pr. 239Î Refer to Pr. 4. Pr. 240Î Refer to Pr. 72. Cooling fan operation selection ( Pr. 244) 4.2.45 Cooling fan operation selection (Pr. 244) Pr. 244 "cooling fan operation selection" You can control the operation of the cooling fan built in the inverter 0.75K or more. (whether there is a cooling fan or not depends on the models. -

Page 161: Slip Compensation (Pr. 245 To Pr. 247)

PARAMETERS Slip compensation (Pr. 245 to Pr. 247) 4.2.46 Slip compensation (Pr. 245 to Pr. 247) Pr. 245 "rated motor slip" Pr. 246 "slip compensation response time" Pr. 247 "constant-output region slip compensation selection" The inverter output current may be used to assume motor slip to keep the motor speed constant. -

Page 162: Stop Selection (Pr. 250)

PARAMETERS Ground fault detection at start (Pr. 249) Stop selection (Pr. 250) 4.2.47 Stop selection (Pr. 250) Related parameters Pr. 250 "stop selection" Pr. 7 "acceleration time" Pr. 8 "deceleration time" Pr. 44 "second acceleration/ deceleration time" Pr. 45 "second deceleration time"... - Page 163 PARAMETERS When the Pr. 250 value is 8888, the functions of terminals STF and STR change as shown below: STF = start signal, STR = rotation direction signal Inverter Operating Status Stop Forward rotation Reverse rotation When the Pr. 250 value is any of 1000 to 1100 seconds, the functions of terminals STF and STR are the same as when the Pr.

-

Page 164: Meter (Frequency Meter) Calibration (Pr. 901)

PARAMETERS Display meter (frequency meter) calibration (Pr. 900) 4.2.48 Meter (frequency meter) calibration (Pr. 901) Related parameters Pr. 901 "AM terminal calibration" Pr. 55 "frequency monitoring reference" Pr. 56 "current monitoring reference" Pr. 158 "AM terminal function selection" z By using the control panel or parameter unit, you can calibrate a meter connected to terminal AM to full scale deflection. - Page 165 PARAMETERS <Operation procedure> y When using the control panel (FR-PA02- 1) Select the PU operation mode. 2) Set the running frequency. 3) Press the key. 4) Read Pr. 901 "AM terminal calibration". 5) Press the key to run the inverter. (Motor need not be connected.) 6) Hold down the key to adjust the meter pointer to a required position.

-

Page 166: Biases And Gains Of The Frequency Setting Voltage (Current)

PARAMETERS Bias and gain of frequency setting voltage (current) and built-in frequency setting potentiometer (Pr. 902 to Pr. 905, Pr. 922, Pr. 923) 4.2.49 Biases and gains of the frequency setting voltage (current) (Pr. 902 to Pr. 905) Related parameters Pr. - Page 167 PARAMETERS Pr. 903 "frequency setting voltage gain" (Pr. 902, Pr. 904, Pr. 905 can also be adjusted similarly.) <Adjustment procedure> W hen using an external frequency setting signal to set the frequency. (1) Power-on (monitoring mode) MODE STOP RESET (2) Choose the PU operation mode. 1) Using the key, make sure that the PU operation mode has been selected.

- Page 168 PARAMETERS 2) Set "1" (PU operation mode) in Pr. 79 "operation mode selection". Example: To change the external operation mode (Pr. 79=2) to the PU operation mode (Pr. 79=1) Using the key, MODE choose the "parameter setting mode" as in 1). Parameter setting mode Most significant Least significant...

- Page 169 PARAMETERS (3) Read Pr. 903 and show the current setting of the gain frequency. (Pr. 902, Pr. 904 and Pr. 905 can also be adjusted similarly.) Parameter setting mode Using the key, choose the MODE "parameter setting mode" as in (2)-1). MODE STOP RESET...

- Page 170 PARAMETERS Î 1) When not adjusting the gain voltage To (5) Î 2) When adjusting any point by applying a voltage To (6) Î 3) When adjusting any point without applying a voltage To (7) (5) How to adjust the gain frequency only without the voltage being adjusted Analog voltage A/D value (%) across Press the...

- Page 171 PARAMETERS (7) How to adjust any point without applying a voltage across terminals 2-5 (without a current flowing across terminals 4-5) (when changing from 4V (80%) to 5V (100%)) Set the gain voltage (%) with Analog voltage A/D key. Press the value (%) across [0(%) for 0V (0mA), 100(%) for once to display the current...

- Page 172 C H A P T E R 5 CHAPTER 5 PROTECTIVE PROTECTIVE FUNCTIONS FUNCTIONS This chapter explains the "protective functions" of this product. Always read the instructions before using the equipment. 5.1 Errors (Alarms) ............157 5.2 Troubleshooting ............166 C hapter 1 5.3 Precautions for Maintenance and Inspection ..

-

Page 173: Protective Functions

5.1 Errors (Alarms) PROTECTIVE FUNCTIONS 5 PROTECTIVE FUNCTIONS 5.1 Errors (Alarms) If any fault has occurred in the inverter, the corresponding protective function is activated to bring the inverter to an alarm stop and automatically give the corresponding error (alarm) indication on the optional control panel or the parameter unit display. If your fault does not correspond to any of the following errors or if you have any other problem, please contact your sales representative. - Page 174 PROTECTIVE FUNCTIONS Operation Panel Indication E. OC3 FR-PU04 OC During Dec Overcurrent shut-off during deceleration Name When the inverter output current reaches or exceeds approximately 200% of the rated current during deceleration Description (other than acceleration or constant speed), the protective circuit is activated to stop the inverter output.

- Page 175 PROTECTIVE FUNCTIONS Operation Panel Indication E. THM FR-PU04 Motor Overload Motor overload shut-off (electronic overcurrent protection) Name (Note 1) The electronic overcurrent protection in the inverter detects motor overheat due to overload or reduced cooling capability Description during constant-speed operation to stop the inverter output. When a multi-pole motor or two or more motors are run, provide a thermal relay in the output side of the inverter.

- Page 176 PROTECTIVE FUNCTIONS Operation Panel Indication E. BE FR-PU04 Br. Cct. Fault (Note) Brake transistor alarm detection (Note 2) Name If a brake transistor fault occurs due to excessively large regenerative energy from the motor, for example, that fault is Description detected to stop the inverter output.

- Page 177 PROTECTIVE FUNCTIONS Operation Panel Indication E.OPT FR-PU04 Option Fault Option alarm Name Stops the inverter output if the inverter station is disconnected from the system in the NET mode. Also stops Description the inverter output if the dedicated option used in the inverter results in setting error or connection (connector) fault.

- Page 178 PROTECTIVE FUNCTIONS E. 6 Fault 6 Operation Panel Indication FR-PU04 E. 7 Fault 7 CPU error Name This function stops the inverter output if a communication Description error occurs in the built-in CPU. Check point Corrective action Please contact your sales representative. Operation Panel Indication E.

- Page 179 PROTECTIVE FUNCTIONS (3) Warnings Operation Panel Indication FR-PU04 OL (Stll Prev STP) Stall prevention (over current) Name During If a current of more than 150% (Note 4) of acceleration the rated inverter current flows in the motor, this function stops the increase in frequency until overload...

- Page 180 PROTECTIVE FUNCTIONS Operation Panel Indication FR-PU04 Stall prevention (overvoltage) Name During If the regenerative energy of the motor deceleration increases too much to exceed the brake capability, this function stops the decrease Description in frequency to prevent overvoltage shut- off. As soon as the regenerative energy has reduced, deceleration resumes.

-

Page 181: To Know The Operating Status At The Occurrence Of Alarm

PROTECTIVE FUNCTIONS 5.1.2 To know the operating status at the occurrence of alarm When any alarm has occurred, the display automatically switches to the indication of the corresponding protective function (error). By pressing the key at this point MODE without resetting the inverter, the display shows the output frequency. In this way, it is possible to know the running frequency at the occurrence of the alarm. -

Page 182: Troubleshooting

5.2 Troubleshooting PROTECTIVE FUNCTIONS 5.2 Troubleshooting POINT:Check the corresponding areas. If the cause is still unknown, it is recommended to initialize the parameters (return to factory settings), re-set the required parameter values, and check again. 5.2.1 Motor remains stopped (1) Check the main circuit Check that a proper power supply voltage is applied (control panel display is provided). -

Page 183: Speed Greatly Differs From The Setting

5.2 Troubleshooting PROTECTIVE FUNCTIONS 5.2.3 Speed greatly differs from the setting Check that the frequency setting signal is correct. (Measure the input signal level.) Check that the following parameter settings are correct (Pr. 1, Pr. 2, Pr. 38, Pr. 39, Pr. 245, Pr. 902 to Pr. 905, Pr. 19). Check that the input signal lines are not affected by external noise. -

Page 184: Operation Mode Is Not Changed Properly

5.2 Troubleshooting PROTECTIVE FUNCTIONS 5.2.8 Operation mode is not changed properly If the operation mode does not change correctly, check the following: ....Check that the STF or STR signal is off. 1. External input signal When it is on, the operation mode cannot be changed. -

Page 185: Precautions For Maintenance And Inspection

5.3 Precautions for Maintenance and Inspection PROTECTIVE FUNCTIONS 5.3 Precautions for Maintenance and Inspection The transistorized inverter is a static unit mainly consisting of semiconductor devices. Daily inspection must be performed to prevent any fault from occurring due to adverse influence by the operating environment, such as temperature, humidity, dust, dirt and vibration, changes in the parts with time, service life, and other factors. -

Page 186: Insulation Resistance Test Using Megger

PROTECTIVE FUNCTIONS 5.3.4 Insulation resistance test using megger (1)Before performing the insulation resistance test using a megger on the external circuit, disconnect the cables from all terminals of the inverter so that the test voltage is not applied to the inverter. (2)For the continuity test of the control circuit, use a meter (high resistance range) and do not use the megger or buzzer. -

Page 187: Daily And Periodic Inspection

PROTECTIVE FUNCTIONS 5.3.6 Daily and Periodic Inspection Interval Periodic* Inspection Description Method Criterion Instrument Item Ambient temperature: -10°C to +50°C, Thermo- Check ambient Surrounding non-freezing. meter, temperature, humidity, Refer to page 11. environment Ambient hygrometer, dust, dirt, etc. humidity: 90% recorder or less, non- condensing. - Page 188 PROTECTIVE FUNCTIONS Interval Periodic* Inspection Description Method Criterion Instrument Item (1) Auditory check. (1) No fault. (1) Check for chatter during operation. (2) Visual check. (2) No fault. Relay (2) Check for rough surface on contacts. (1) Check balance of (1) Measure voltage (1) Phase-to- output voltages...

- Page 189 PROTECTIVE FUNCTIONS z Checking the inverter and converter modules <Preparation> (1)Disconnect the external power supply cables (L ) and motor cables (U, V, (2)Prepare a meter. (Use 100Ω range.) <Checking method> Change the polarity of the meter alternately at the inverter terminals L U, V, W, + and −, and check for continuity.

-

Page 190: Replacement Of Parts

PROTECTIVE FUNCTIONS 5.3.7 Replacement of parts The inverter consists of many electronic parts such as semiconductor devices. The following parts may deteriorate with age because of their structural or physical characteristics, leading to reduced performance or failure of the inverter. For preventive maintenance, the parts must be changed periodically. - Page 191 PROTECTIVE FUNCTIONS z Removal 1) Remove the front cover (refer to page 5). 2) Unplug the fan connector. The cooling fan is connected to the cooling fan connector beside the main circuit terminal block of the inverter. Unplug the connector. Fan connector 3) Remove the inverter and cooling fan.

- Page 192 PROTECTIVE FUNCTIONS z Reinstallation 1) After confirming the orientation of the fan, reinstall the fan to the ↑AIR FLOW cover so that the arrow on the left of "AIR FLOW" faces in the opposite direction of the fan cover. Note: If the air flow is set in the wrong direction, the inverter life can be...

- Page 193 PROTECTIVE FUNCTIONS (2) Smoothing capacitors A large-capacity aluminum electrolytic capacitor is used for smoothing the DC in the main circuit, and an aluminum electrolytic capacitor is also used for stabilizing the control power in the control circuit. Their characteristics are adversely affected by ripple current, etc. When the inverter is operated in an ordinary, air-conditioned environment, change the capacitors about every 5 years.

-

Page 194: Measurement Of Main Circuit Voltages, Currents And Powers

PROTECTIVE FUNCTIONS 5.3.8 Measurement of main circuit voltages, currents and powers z Measurement of voltages and currents Since the voltages and currents on the inverter power supply and output sides include harmonics, accurate measurement depends on the instruments used and circuits measured. When instruments for commercial frequency are used for measurement, measure the following circuits using the instruments given on the next page. - Page 195 PROTECTIVE FUNCTIONS Measuring Points and Instruments Remarks Item Measuring Point Measuring Instrument (Reference Measured Value) Power supply Is the commercial power supply Moving-iron type AC voltage Across L within permissible variation of AC voltmeter (V1) voltage (Refer to page 180) Power supply side Moving-iron type AC current...

-

Page 196: Specifications

CHAPTER 6 SPECIFICATIONS This chapter provides the "specifications" of this product. Always read the instructions before using the equipment 6.1 Standard Specifications .......... 180 C hapter 1 C hapter 2 C hapter 3 C hapter 4 C hapter 5 C hapter 6... -

Page 197: Standard Specifications

6.1 Standard Specifications SPECIFICATIONS 6 SPECIFICATIONS 6.1 Standard Specifications 6.1.1 Model specifications (1) 3-phase 400V power supply Type FR-E540- K-EC 0.75 Applicable motor capacity (kW) 0.75 (Note 1) Rated capacity (kVA) (Note 2) 13.0 Rated current (A) (Note 6) 1.6(1.4) 2.6(2.2) 4(3.8) 6(5.4) 9.5(8.7) 150% 60 s 200% 0.5 s Overload capacity... - Page 198 SPECIFICATIONS (2) Single-phase 200V power supply Type FR-E520S- K-EC 0.75 Applicable motor capacity (kW) 0.75 (Note 1) Rated capacity (kVA) (Note 2) 0.95 Rated output current (A) Overload capacity (Note 3) 150% 60 s 200% 0.5 s (inverse-time characteristics) Rated output voltage(Note 4) Three phase, 200V to 240V 50Hz/60Hz Rated input AC voltage, Single phase, 200V to 240V 50Hz/60Hz...

-

Page 199: Common Specifications

SPECIFICATIONS 6.1.2 Common specifications Soft-PWM control/high carrier frequency PWM control can be selected. Control system V/F control or general-purpose magnetic flux vector control can be selected. Output frequency range 0.2 to 400Hz (starting frequency variable between 0 and 60Hz) Across terminals 2-5: 1/500 of maximum set frequency (5VDC input), Analog input Frequency 1/1000 (10VDC, 4-20mADC input). - Page 200 SPECIFICATIONS Maximum/minimum frequency setting, frequency jump operation, external thermal relay input selection, automatic restart operation after Operation functions instantaneous power failure, forward/reverse rotation prevention, slip compensation, operation mode selection, offline auto tuning function, PID control, computer link operation (RS-485). 2 open collector output signals can be selected from inverter running, up to frequency, frequency detection, overload alarm, zero current Operating status detection, output current detection, PID upper limit, PID lower limit, PID...

-

Page 201: Outline Drawings

SPECIFICATIONS 6.1.3 Outline drawings z FR-E540-0.4K, 0.75K, 1.5K, 2.2K, 3.7K-EC z FR-E520S-0.4K, 0.75K, 1.5K, 2.2K-EC 2-φ5 hole Inverter Type FR-E540-0.4K, 0.75K-EC 116 44 FR-E540-1.5K to 3.7K-EC 136 64 FR-E520S-0.4K, 0.75K-EC 136 64 FR-E520S-1.5K, 2.2K-EC 156 84 Cooling fan × 1 Note: There is no cooling fan in the FR-E540-0.4K, 0.75K-EC and FR-E520S-0.4K, 0.75K-EC. - Page 202 SPECIFICATIONS z FR-E540-5.5K, 7.5K-EC 2-φ5 hole Cooling fan × 2 (Unit: mm)

-

Page 203: Appendix

APPENDIX A P P E N D I X This chapter provides "supplementary information" for use of this product. Always read the instructions before using the equipment. Appendix 1 Data Code List .......... 186... -

Page 204: Appendix 1 Data Code List

Appendix 1 Data Code List APPENDIX Appendix 1 Data Code List Link Parameter Extension Setting Func- Parameter Data Code Name (Data Code 7F/FF) tion Number Read Write Torque boost Maximum frequency Minimum frequency Base frequency Multi-speed setting (high speed) Multi-speed setting (middle speed) Multi-speed setting (low speed) Acceleration time Deceleration time... - Page 205 Link Parameter Extension Setting Func- Parameter Data Code Name (Data Code 7F/FF) tion Number Read Write Up-to-frequency sensitivity Output frequency detection Output frequency detection for reverse rotation Second acceleration/deceleration time Second deceleration time Second torque boost Second V/F (base frequency) Second electronic overcurrent protection Control panel/PU main display...

- Page 206 Link Parameter Extension Setting Func- Parameter Data Code Name (Data Code 7F/FF) tion Number Read Write Motor capacity Motor exciting current Rated motor voltage Rated motor frequency Motor constant (R1) Auto-tuning setting/status Station number Communication speed Stop bit length Parity check presence/absence Number of communication retries Communication check time interval...

- Page 207 Link Parameter Extension Setting Data Code Func- Parameter Name (Data Code 7F/FF) tion Number Read Write RL terminal function selection RM terminal function selection RH terminal function selection MRS terminal function selection RUN terminal function selection FU terminal function selection A, B, C terminal function selection Multi-speed setting (speed 8) Multi-speed setting (speed 9)

- Page 208 REVISIONS *The manual number is given on the bottom left of the back cover. Print Date Revision *Manual Number Mar., 1999 IB(NA)-0600002-A First edition Apr., 1999 IB(NA)-0600002-B Modifications •Instructions for compliance with the UL and CSA standards Factory setting of Pr. 4 "Multi-speed setting (high speed)" Jun., 1999 IB(NA)-0600002-C Modifications Pr.