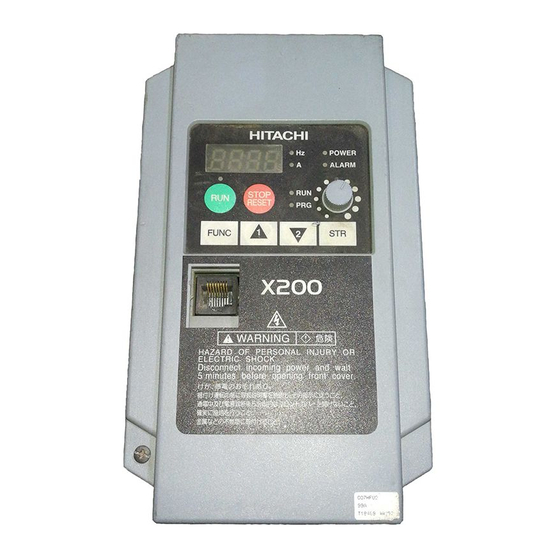

Hitachi X200 Series Manuals

Manuals and User Guides for Hitachi X200 Series. We have 4 Hitachi X200 Series manuals available for free PDF download: Instruction Manual, Connection Manual, Quick Reference Manual

Advertisement

Hitachi X200 Series Instruction Manual (305 pages)

Single-phase Input 200V class; Three-phase Input 200V class; Three-phase Input 400V class

Table of Contents

Advertisement

Advertisement