Summary of Contents for Siemens 3AH47

- Page 1 3AH47 Vacuum circuit-breaker 17.5 kV - 16.7 Hz and 27.5 kV - 50/60 Hz OPERATING INSTRUCTIONS Order no.: 9229 9947 176 0C Ordering location: IC LMV LP PO P C41 AG 03.2013 en © Siemens AG 1996. All rights reserved.

-

Page 2: For Your Safety

• training in providing first aid. Product liability Note Product liability claims are upheld only if the replacement of the purchased spare parts is performed by personnel that has been trained and certified by Siemens. 9229 9947 176 0C 2013-03-28... -

Page 3: Table Of Contents

Sections with Addendum (I) are about the standard equipment. Sections with Addendum (II) relate only to vacuum circuit-breakers with two vacuum-interrupters connected in series. If no addendum is given, the information is applicable for all 3AH47 vacuum circuit-breakers. 9229 9947 176 0C... - Page 4 Blank page 9229 9947 176 0C 2013-03-28...

-

Page 5: Transport, Storage And Packing

Transport, storage and packing Transport, storage and packing Transport WARNING Heavy transport weight Transport unit may fall and fail and sling gear may break. Use means of lifting, transporting and sling gear suited to the requirements and load-carrying capacity. Observe transport symbols. Refer to the delivery slip for the weight of the transport unit. -

Page 6: Unpacking (I)

Transport, storage and packing Transport the transport unit to the installation site or storage location Transport with packing • with a fork lift or • with sling gear suspended from a crane at an angle of twist of approx. 60° or with a spreader bar. - Page 7 Transport, storage and packing • Place the transport unit on a level, non-slip and pressure-resistant surface. Opening the transport unit • Remove lifting gear or transport means. • Remove plastic wrap. • Lever out fasteners from the carton and lift off carton. Note Do not use the vacuum circuit-breaker if parts are broken, i.e.

- Page 8 Transport, storage and packing Note When fastening the eyebolts to the pole heads, ensure that the contact surfaces are not damaged. Fig. 6 Removing the tensioning belts Fig. 7 Screwing in eye bolts and lifting the vacuum circuit-breaker • Remove all tensioning belts and bits of fastening wood. Transport without pallet •...

- Page 9 Transport, storage and packing Fig. 8 Positioning the square timbers and setting Fig. 9 Transporting without pallet down the vacuum circuit-breaker • Set the vacuum circuit-breaker down onto the square timbers. • Hang further sling gear into the transport boreholes. •...

-

Page 10: Unpacking (Ii)

Transport, storage and packing Unpacking (II) Required tools: Working equipment Knife/scissors Lifting equipment with lifting gear. Note Do not use the vacuum circuit-breaker if parts are broken, i.e. if you find cracks, flakings, bent metal parts, damaged plug-in contacts, tears or bare cables. Send it back in its original transport unit (see “Reusing the transport unit”, page 12). - Page 11 Transport, storage and packing CAUTION Crushing hazard! The vacuum circuit-breaker can tip during lifting and crush hands. Do not reach between pole head and beam. Reposition the vacuum circuit-breaker. Wear helmet and gloves. Note The vacuum circuit-breaker has a tilted transport position because the centre of gravity is situated outside of the mechanism box.

-

Page 12: Reusing The Transport Unit

• Screw the wooden case back together. • Before returning to the factory, ask the responsible Siemens representative for a returned goods number (see also “Service”, on page 55). • When returning a vacuum circuit-breaker, always indicate the type and serial number (see “Rating plate”, on page 31). -

Page 13: General Information

3AH47 vacuum circuit-breakers are one-pole or two-pole interior circuit-breakers for a rated voltage of 17.5 kV - 27.5 kV. 3AH47 vacuum circuit-breakers can handle up to 60 000 operating cycles if the maintenance schedule is observed. 3AH47 vacuum circuit-breakers are suitable for switching any type of alternating... -

Page 14: Standards

IEC 62271-1 • IEC (DIN EN) 60265-1 All 3AH47 vacuum circuit-breakers comply with the specifications for C2-, E2- and M2-class circuit-breakers in accordance with IEC 62271-100. Design approval as per X-Ray Ordinance The vacuum interrupters installed in the vacuum circuit-breakers are of a design approved under the X-Ray Ordinance (RöV) of the Federal Republic of Germany. -

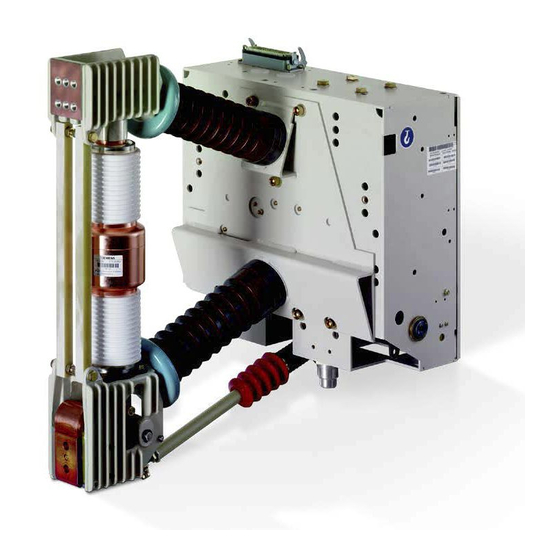

Page 15: Description

Description Description Design The 3AH47 vacuum circuit-breakers differ in their outer design: • One-pole with two vacuum interrupters arranged one above the other • One-pole with a vacuum interrupter • Two-pole with one vacuum interrupter per pole The basic design as well as the operating mechanisms are the same for all types of construction. - Page 16 Description The pole assembly (19.) of the 3AH47 vacuum circuit-breaker consists of Pole assembly • the upper interrupter support (20.) • with the upper terminal (27.) • of the vacuum interrupter (30.); • the lower interrupter support (40.) with the lower terminal (29.) and the clamp (29.2) with flexible connector (29.1);...

- Page 17 Description Contact system in the vacuum interrupters A slight change in the contact stroke that occurs over the entire useful life of the vacuum interrupter has no effect on its function. There is no need for a status indicator for the contact system. The mechanism box (60.) contains all the electrical and mechanical components Mechanism box required to switch the vacuum circuit-breaker on or off.

- Page 18 Description Fig. 20 Opened mechanism box 50.2 Gear unit Contact position indicator CLOSED-OPEN 50.4 Motor M1 Mechanism box 50.4.1 Position switch Dashpot 50.5 Hand crank coupling Closing spring Rating plate Circuit-breaker shaft 53.1 Closing solenoid Y9 Opening spring 54.1 Shunt release Y1 Closing damper 54.2 Shunt release Y2 or...

- Page 19 Plug-connector with sleeve housing 24-pin • Terminal strip Operating cycle counter Mechanical anti-pumping device Mechanical manual closing and opening Every 3AH47 vacuum circuit-breaker can be fitted with the following equipment: Additional equipment (Y2, Y3) Shunt release 3AX1101 (Y4, Y5) Transformer-operated release 3AX1102 (Y6) Transformer-operated release 3AX1104 (0.1 AC)

- Page 20 Description Motor (M1) After the supply voltage is applied and if the closing spring is relaxed, the motor starts immediately and is automatically deactivated internally after charging has taken place. Power consumption, maximum: • in the event of direct voltage approx. 750 W •...

- Page 21 Description Closing solenoid (Y9) 3AY1510 The closing solenoid Y9 unlatches the charged closing spring and switches the vacuum circuit-breaker on electrically. It is available for DC or AC voltage. The closing solenoid Y9 is not designed for continuous operation and is automatically deactivated within the circuit-breaker.

- Page 22 Description Auxiliary switch S1 Three versions of the auxiliary switch S1 are available for delivery: with 6 or 12 NO / NC contacts each. Rated insulation voltage: 250 V AC/DC Insulation group: C as per VDE 0110 Continuous current: 10 A Closing capacity: 50 A Fig.

- Page 23 Description Position switch S21, S22 Position switches (switch off the motor after charging) Position switch (opens when closing spring is charged) S41, S42 Position switches (report charging state) Fig. 28 Position switch (50.4.1) Circuit-breaker tripping signal, cut-out switch (S6, S7) The position switch S6 makes contact briefly when the vacuum circuit-breaker is opened by means of an electrical release.

- Page 24 Description Low-voltage interface X0, 64-pin Fig. 30 Low-voltage interface X0 Fig. 31 Terminal strip (optional) For connection of the control line, the standard version of the vacuum circuit- breakers are equipped with a 64-pin low-voltage interface X0 (68.7). The 64-pin plug (68.7.1) for the external terminal, is suitable for crimp termination of control lines with a nominal cross-section of 1.5 mm Instead of the 64-pin plug (68.7.1), a terminal strip (68.7.2) can be ordered as Terminal strip (optional)

- Page 25 Description A further shunt release, transformer-operated release, undervoltage release or instantaneous release can be installed as a 2nd release. 2nd shunt release (Y2) 3AX1101 The second shunt release Y2 is installed whenever more than one shunt release is needed. In this version, the electrical “off” command is passed by means of a magnet armature to the "OPENING"...

- Page 26 Description Undervoltage release (Y7) 3AX1103 Note The undervoltage release Y7 must only be operated with the supplied series resistor R1. Note For switching operations (mechanical or electrical), the undervoltage release 3AX1103… must be connected to control voltage, as otherwise closing is not possible.

- Page 27 Closing time operating time of < 10 ms, at a very small magnet stroke of 2.5 mm. For use in the 3AH47 vacuum circuit-breaker a dynamic method of working is therefore selected: Because the tripping stroke is not sufficient for static tripping of the opening latch, a tripping lever is quickly accelerated and actuates the latch with its kinetic energy.

- Page 28 Description Note When an instantaneous release H83 Opt. is used, no 3rd release can be ordered and used. The capacitor tripping unit 3AX1550 and the transistor switch (MOSFET) are not included in the scope of supply and must be ordered separately. Heater (condensation water protection) The heater limits condensation and corrosion of the vacuum circuit-breaker.

-

Page 29: Interlocking Devices

Description Interlocking devices To lock vacuum circuit-breakers as a function of the switching position, the spring drive mechanisms of the vacuum circuit-breaker can be equipped with an interlocking device. This is also the case for vacuum circuit-breakers on switch gear trucks, in withdrawable sections or with disconnectors. - Page 30 Description Priority opening To lock vacuum circuit-breakers, switchgear trucks, withdrawable sections or disconnectors in OPEN position, the drive mechanisms of the vacuum circuit- breaker can be equipped with "priority opening". Idle position Trip-free position Spring-dump position Interrogation or actuation component (max. actuation force 70 N) Fig.

-

Page 31: Rating Plate

Dimensions and weights The dimensions of the vacuum circuit-breaker can be taken from the relevant dimension drawing. If required, these are available from your Siemens representative. The weight is given on the rating plate of the vacuum circuit-breaker (see Fig. 40) or can be taken from the relevant dimension drawing. -

Page 32: Ambient Conditions

Description Ambient conditions 3AH47 vacuum circuit-breakers are suitable for use in the following climate classes in accordance with IEC 60721, Part 3-3: Class • Climatic ambient conditions: 3Z2, • Biological ambient conditions: • Mechanical ambient conditions: • Chemically active substances: •... -

Page 33: Switching Times

Description Switching times Closing time (closing time) < 75 ms Opening time (opening time) 1st shunt release (Y1) < 60 ms 2nd and 3rd release (Y2, Y4, Y6, Y7) < 55 ms Arcing time < 15 ms Break time 1st shunt release (Y1) <... -

Page 34: Circuit Diagrams

Description Circuit diagrams The circuit diagrams show all the available components with their wiring options. Fig. 45 to Fig. 51 show some non-binding examples of vacuum circuit-breakers. Compilation of the circuit diagrams for the vacuum circuit-breaker is done in relation to your order. - Page 35 Description 1) Integrated varistor 2) Integrated rectifier for AC/DC≥ 100 V 3) Line H07V-K1x2.5sw (as per EN 50525-2-31) when motors are used with DC 24 V / 48 V and 60 V 4) Only if a mechanical closing lock is ordered at the same time a) Motor winding for DC b) Motor winding with rectifier for AC c) Closing...

- Page 36 Description 1) Integrated varistor 2) Integrated rectifier for AC/DC≥ 100 V a) 1st shunt release with 64-pole plug-connector b) 1st shunt release with 24-pole plug-connector c) 2nd shunt release with 64-pole plug-connector d) 2nd shunt release with 24-pole plug-connector Fig. 48 Sample circuit diagram (part 2) of the vacuum circuit-breaker 9229 9947 176 0C 2013-03-28...

- Page 37 Description 1) Integrated varistor 2) Integrated rectifier for AC/DC≥ 100 V 3) Attention: connect L+ for direct current (DC) a) Undervoltage release b) Low-energy trip-coil c) 1st transformer-operated release d) Signal: spring state with 64-pole plug-connector e) Signal: spring state with 24-pole plug-connector Breaker tripping signal for 64-pole plug-connector Fig.

- Page 38 Description The unassigned auxiliary switch terminals are wired up with the 64-pole plug bottom. Normal auxiliary switch Extended auxiliary switch No wiring required if a) 2nd shunt release Y2 available b) Undervoltage release Y7 available Fig. 50 Example – auxiliary switch terminals System wiring Tripping via Tripping via NO...

-

Page 39: Installation

Installation Installation DANGER High-voltage – danger to life Touching live parts causes an electric shock. • Do not touch live parts! • When performing work on the switchgear, deenergize it and earth it. • The work described in the following sections must only be performed when the switchgear has been deenergized: Take safety measures to prevent reclosing. - Page 40 Installation The 3AH47 vacuum circuit-breaker can only be installed horizontally (to the vacuum Mounting position interrupter), as an indoor withdrawable section and as an indoor fixed installation. Fig. 52 Mounting position Mounting the vacuum circuit-breaker There are a total of 14 fixing holes on the pole plate (15) and on the mechanism box (60.) for the various types of installation.

-

Page 41: Earthing

Tighten ring terminal of the earth wire with the M12 hexagon socket head screw on the earth terminal (70.) with 40 Nm. Note If the 3AH47 vacuum circuit-breaker is installed into a earthed metal frame and is connected permanently and electrically conductive, no separate earthing needs to be done. - Page 42 Installation Removing the transport securing device from the undervoltage release The vacuum circuit-breaker with an undervoltage release (Y7) 3AX1103 is supplied Undervoltage release (Y7) with a transport securing device. available? • Remove the two top screws (60.2) of the mechanism box. •...

-

Page 43: Electrical Connection Of The Prime Conductor

45). Note Grease the busbars with contact grease prior to mounting. The busbars can be purchased from the Siemens Service Center. Busbar connection Adjust the busbars in such a way that, before fastening, they lie flat easily and fit the holes on the contact areas of the vacuum circuit-breaker. - Page 44 Installation Fig. 61 Installing busbars flat Fig. 62 Installing busbars flat Corresponding to the nominal current strength, use M12 screws and nuts - strength class 8.8 - for connection and appropriate spring elements and washers. Note For vacuum circuit-breakers with connecting bars it is recommended to use the stainless steel screws or non-magnetisable screws included in the accessory pack.

-

Page 45: Operation

• Check through all of the items on the checklist and ensure correct functioning before commissioning. Commissioning Before commissioning, check the following points to ensure that the 3AH47 vacuum circuit-breaker based is functioning faultlessly: Checklist Notes Does the information on the rating plate (see page 31) match the ordering data? Ensure correct operating voltage. -

Page 46: First Closing Operation

Operation WARNING Do not commission the vacuum circuit-breaker if there are malfunctions. If the malfunctions or the damage cannot be remedied, contact a Siemens representative or Siemens Service and, if necessary, send back the vacuum circuit-breaker. First closing operation If all functions have been checked and are ok, switch on high-voltage while observing all of the safety regulations and operative requirements. -

Page 47: Closing

Operation The adapter (50.6) of the hand crank (50.) is designed in such a way that the hand crank becomes uncoupled when the motor supply voltage returns. Closing Provided there is no lock-out due to a mechanical interlock, send the closing command via the CLOSED pushbutton (53.) or the corresponding command element until the vacuum circuit-breaker is closed and shows and signals the CLOSED position. - Page 48 Operation Blank page 9229 9947 176 0C 2013-03-28...

-

Page 49: Maintenance

Maintenance Maintenance Maintenance and servicing DANGER High-voltage – danger to life Touching live parts is fatal or causes serious physical injury. Before beginning maintenance work, note the five safety rules for high-voltage equipment specified in EN 50110-1, namely: • Isolate from the power supply* •... -

Page 50: Maintenance Plan

Maintenance Maintenance plan Work to be done Operating and Frequency Remarks auxiliary materials mechanical operating cycles Vacuum circuit-breaker Clean insulating parts and outer Warm water, Note 1) parts household cleaners Check tripping system for Isoflex Topas L 32 with instantaneous release unencumbered movement and Shell Tellus oil 32 Note 2), 3) - Page 51 4) On all the exchanged parts, the locking elements used must be exchanged as well (spring rings, SL retainers, cotter-pins etc.). The Siemens sales representative offers an assortment of locking elements. Order no. 3AY1550-1A 5) Position switches must only be fastened so tight that the tappet is easily moved.

- Page 52 Maintenance Isoflex Topas L 32 Shell Tellus oil 32 Crankpin for sensing device actuation Bearing for deflection lever Curve contour Auxiliary switch Close-latch Circuit-breaker shaft bearing Deflection of auxiliary switch Opening spring bearing Opening spring guide Spring eyelet on closing spring Deflection of auxiliary switch OPEN-latch Curve for OPEN-latch...

- Page 53 Maintenance 7) Adjusting the contact stroke: Due to erosion and mechanical deformation (compression) of the contacts, the contact stroke increases and the contact force is reduced. In order to maintain break-times within the specified tolerances, the increase in the stroke may not be more than 2 mm.

-

Page 54: Vacuum Interrupter Service Life

Maintenance Vacuum interrupter service life If switching operations occur frequently under overload or short circuit, the service life of the vacuum interrupters may be reached prematurely. After reaching the maximum permissible number of operating cycles of: VS 10047/48 = 60 000 VS 30029/30, VS 30040/41, VS 36025 L = 30 000 mechanical or electrical load changes (to the rated current), the vacuum interrupters... -

Page 55: Manufacturer's Product Liability

Republic of Germany, the applicable local laws and regulations must be complied with. Contact your Siemens Service Center if you require further information. Further information Service For details of contacts for service work, consult Siemens IC LMV SE Services at • Telephone: +49 180/5247000 • Fax: +49 180/5242471 or •... - Page 56 Maintenance Blank page 9229 9947 176 0C 2013-03-28...

-

Page 57: Index Of Keywords

Index of keywords Index of keywords Mechanical manual opening ........19 Mechanism box ..........15 Accessories to be ordered ........54 Mechanism box, opened ........18 Altitude correction factor ........32 Motor ............18 Ambient conditions ..........32 Mounting position ..........40 Angle lever ............ - Page 58 Index of keywords Blank page 9229 9947 176 0C 2013-03-28...

-

Page 59: Legend For All Pages

Legend for all pages Legend for all pages Pole plate 60.1 Cover 16.1 Upper post insulator 60.2 Transport borehole 16.2 Lower post insulator 60.3 Crane hook symbol Pole assembly, complete Dashpot Upper interrupter support Closing spring Upper terminal Circuit-breaker shaft Strut Opening spring 28.1... - Page 60 Published by Siemens AG Infrastructure & Cities Sector Low and Medium Voltage Division Medium Voltage & Systems Schaltwerk Berlin Nonnendammallee 104 13629 Berlin...