Table of Contents

Advertisement

Quick Links

SITRANS

Sensing Heads

SITRANS WFS300

Operating Instructions

03/2021

A5E32880243-AC

Introduction

Safety notes

Description

Installing/mounting

Connecting

Commissioning

Service and maintenance

Diagnosing and

troubleshooting

Technical specifications

Dimension drawings

Appendix A

Product documentation and

support

1

2

3

4

5

6

7

8

9

10

A

B

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Siemens SITRANS WFS300

- Page 1 Introduction Safety notes SITRANS Description Installing/mounting Sensing Heads SITRANS WFS300 Connecting Commissioning Operating Instructions Service and maintenance Diagnosing and troubleshooting Technical specifications Dimension drawings Appendix A Product documentation and support 03/2021 A5E32880243-AC...

- Page 2 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 3: Table Of Contents

The manual ......................... 5 Safety notes ............................6 General safety instructions ....................6 Installation in hazardous areas ..................... 6 Description ............................10 SITRANS WFS300 ....................... 10 Principle of operation ......................10 Installing/mounting ..........................12 Sensing head ........................12 4.1.1 Side mount ........................12 4.1.2... - Page 4 WFS300 base mount outline and mounting ................ 37 Appendix A ............................38 WFS300 part identification diagram ................... 38 Product documentation and support ....................40 Product documentation ..................... 40 Technical support ......................41 Index ..............................42 SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 5: Introduction

This manual covers only sensing head installation, operation, and maintenance procedures. Flowmeter and integrator instruction manuals are available for download from our web site: Siemens weighing (http://www.siemens.com/weighing) Follow these operating instructions for quick, trouble-free installation, and maximum accuracy and reliability of your device. -

Page 6: Safety Notes

Installation in hazardous areas WARNING Equipment used in hazardous areas must be Ex-approved and marked accordingly. It is required that the special conditions for safe use provided in the manual and in the Ex certificate are followed. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... - Page 7 3. Per FM13ATEX0032X, the equipment may be used with flammable gases and vapors with apparatus group IIA, IIB, and IIC, and temperature classes T1, T2, T3, T4, T5, and T6 in zone 2 hazardous locations. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

- Page 8 • The enclosure is non-conducting and, under certain extreme conditions, may generate an ignition-capable level of electrostatic charges. The user shall ensure that the equipment is not installed in a location where it may be subjected to external conditions (such as high- SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

- Page 9 In the event of rare incidents, ignition sources due to impact and friction sparks could occur. This shall be considered when the WFS300 is being installed in locations that specifically require Equipment Protection Level Db. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 10: Description

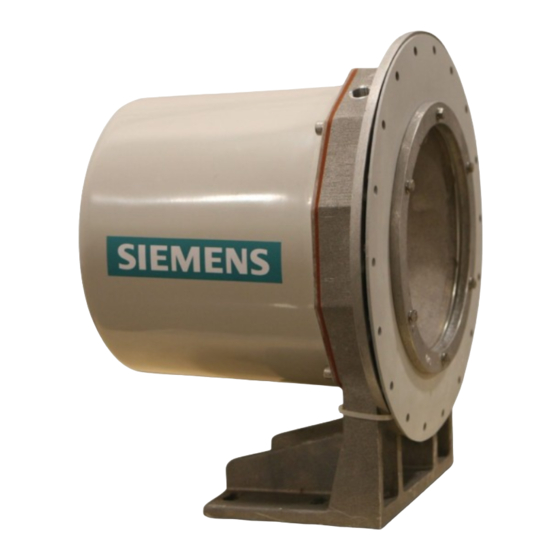

Description SITRANS WFS300 SITRANS WFS300 sensing head is an out-of-process sensing element used for continuous in- line weighing of powdered or granular dry bulk solid materials. It is used with the 40 tph versions of SITRANS WF330 (general purpose), WF340 (vertical material drop), and WF350 (aerated gravity conveyor) dry solids flowmeters. - Page 11 Description 3.2 Principle of operation ① Impact force ③ Moving beam travel ② LVDT ④ Sensing plate SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 12: Installing/Mounting

1 t/h, or if handling product temperatures above 60 °C. The side mount version is factory-installed on Siemens flowmeters designed for side mount sensing heads. 4.1.1 Side mount 1. -

Page 13: Base Mount

Note Ensure that the slot in the end of the shaft mates with the roll pin in the back of the socket. 3. Tighten the set screw/hex screw to secure the sensing plate. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 14: Viscous Damper

The damper must be full and free of air bubbles, with the damper cover in the UP position, during flowmeter operation. ① Sensing head ④ Shipping screws ② Damper ⑤ Damper cover ③ Filler bottle ⑥ Check that there are no bubbles SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 15: Connecting

• GRN = YELLOW LVDT Integrator (Non-hazardous) (LVDT connection) ① Green ⑨ SIG- ② Black No connection ③ Yellow ⑧ COM ④ Blue ⑦ EXC- ⑤ Red ⑥ EXC+ Note Ground shield at Integrator only. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 16: Unit With Sensing Head Mounted Lvdt Conditioner Card

Not applicable to Hazardous-rated units. LVDT to SF500 Integrator LVDT to LVDT conditioner card connections are made by Siemens. *Where separation between the integrator and LVDT conditioner exceeds 150 m (500 ft): 1. Remove the jumpers from SF500 terminals 11/12 and 13/14. - Page 17 5.2 Unit with sensing head mounted LVDT conditioner card Shields are common, but not grounded to chassis. Run cable shields through SHLD terminals ♦ and ground at Integrator only. Note Ensure that the connection between TB-2 and TB-17 is made. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

- Page 18 Connecting 5.2 Unit with sensing head mounted LVDT conditioner card LVDT to SIWAREX FTC LVDT to LVDT conditioner card connections are made by Siemens. Connect the shield to the spring clamp shielding element that is mounted below the FTC. ♦...

-

Page 19: Unit With Remote-Located Lvdt Conditioner Card

– from SF500 terminal 12 to conditioner terminal block marked "Integrator EXC+" – from SF500 terminal 13 to conditioner terminal block marked "Integrator EXC-" For further connection information on specific LVDTs, consult Siemens. ** For Encapsulated LVDT (hazardous) • YEL = WHITE •... - Page 20 Shields are common, but not grounded to chassis. Run cable shields through SHLD terminals ♦ and ground at Integrator only. Note Ensure that the connection between TB-2 and TB-17 is made. Note Junction box included with hazardous-rated unit. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

- Page 21 • BLU = ORANGE • BLK = Not connected • BLU = ORANGE • GRN = YELLOW ***The LVDT can be installed in a hazardous area, but all other components must be in a non-hazardous area. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

- Page 22 5.3 Unit with remote-located LVDT conditioner card Connect the shield to the spring clamp shielding element that is mounted below the FTC. ♦ See FTC manual for details. Note Junction box included with hazardous-rated unit. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 23: Commissioning

*For WF350 flowmeters, use 80 grams (instead of 65 grams) when calculating Test Rate or Test Weight. Example If the test weight used with a WF330 flowmeter is 500 grams: Note Use metric tons per hour (t/h) or short tons per hour (STPH) as applicable for TPH. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 24: Lvdt Output

– Tighten the locknut, ensuring the measured value is maintained. ① Locknut ③ LVDT core ② Moving beam ④ LVDT Note Ensure the new position of the LVDT core allows free movement within the LVDT bore. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 25: Span Test

2. Remove the test weight and readjust the LVDT Output Zero, if necessary. If the level test is performed after the integrator has been calibrated, a new integrator zero and span calibration, span adjust, and factoring, should be performed. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 26: Integrator Calibration

1. Attach one end of a string (monofilament fishing line or fine flexible cable) to the test weight. 2. Route the other end of the string over the calibration pulley. 3. Attach the free end of the string to the string fixing bolt. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... - Page 27 • there is no material flow during zero and span calibrations • the test weight is suspended free of any obstructions Accurate calibration is not assured until material tests and a manual span adjustment have been performed, as outlined in the Integrator operating instructions. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 28: Service And Maintenance

• sensing head outer gasket (base mount version only) • damping fluid • sensing plate Contact Siemens or your distributor for spare parts ordering information. For a list of parts and part identification diagram, please see Appendix A (Page 38). Unit repair and excluded liability All changes and repairs must be done by qualified personnel and applicable safety regulations must be followed. -

Page 29: Inner Gasket Replacement

7. Install the new inner gasket and reverse the procedure (steps 1 through 6). 8. Perform the LVDT output zero procedure. 9. Referring to the integrator operating instructions, perform an integrator zero and span calibration. Perform a span adjust if calibration accuracy appears affected. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 30: Diagnosing And Troubleshooting

After you have removed and replaced the range spring, recalibrate the flowmeter and integrator. (See the Integrator operating instructions for details.) 1. Perform the LVDT output zero procedure. 2. Perform an integrator zero and span calibration. 3. Perform a span adjust and factoring as required. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 31: Troubleshooting

• 780 g (1.72 lb) = 100% Design Rate = 12.0 TPH • 585 g (1.29 lb) = 75% Design Rate = 9.0 TPH • 390 g (0.86 lb) = 50% Design Rate = 6.0 TPH SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... - Page 32 Some integrators are equipped with a linearization function to compensate for non-linear material flow patterns. Stand-alone linearizing devices are also available for this purpose. Electronic linearization should not be used to correct non-linear test weight results. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 33: Technical Specifications

150 m (500 ft) maxi- ®1 for connection between conditioner card and 20 AWG (0.5mm ) or equivalent integrator Belden 9260, 6 conductor , shielded 20 AWG 300 m (1000 ft) max- (0.5 mm ) or equivalent imum SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 34: Input

0 to 0.75 V AC from LVDT LVDT conditioner card Output Output 0 to 50 mV DC to Siemens integrator; maximum 300 m (1000 ft) separation between conditioner LVDT conditioner card card and integrator Output 0 - 0.75 V AC @ 2.9 kHz... -

Page 35: Approvals

IECEx FMG 13.0016X, Ex nA IIC T6 Gc, Ex International tb IIIC T70 ºC Db IP64 Non-Sparking/ Flame- Ex tb IIIC T70°C Db X Russia proof 2Ex nA IIC T6 GC X LVDT conditioner General purpose CE, RCM card approvals SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 36: Dimension Drawings

250 mm (9.84") BCD dimension from the sensing head mounting hole to the flowguide cen- terline. ④ Outer gasket Note Ensure that the outer gasket seal to the flowmeter housing wall is dust tight. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 37: Wfs300 Base Mount Outline And Mounting

Note 1. The sensing head support plate should be rigid and independent of the flowmeter housing. 2. Ensure that the outer gasket seal to the flowmeter housing wall is dust tight. SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... -

Page 38: Wfs300 Part Identification Diagram

Appendix A WFS300 part identification diagram SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC... - Page 39 Nut M8, stainless (18) (base mount only) 41 Cap Screw M8 x 20 mm, stainless (4) Cap Screw M6 x 25 mm, stainless (6) (base mount only) 42 Cap Screw M8 x 30 mm, stainless (3) SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...

-

Page 40: Product Documentation And Support

Entering a serial number 1. Open the PIA Life Cycle Portal (https://www.pia-portal.automation.siemens.com). 2. Select the desired language. 3. Enter the serial number of your device. The product documentation relevant for your device is displayed and can be downloaded. -

Page 41: Technical Support

In addition to our technical support, Siemens offers comprehensive online services at Service & Support (http://www.siemens.com/automation/serviceandsupport). Contact If you have further questions about the device, contact your local Siemens representative at Personal Contact (http://www.automation.siemens.com/partner). To find the contact for your product, go to "all products and branches" and select "Products &... -

Page 42: Index

Customer Support, (Refer to Technical support) Downloads, 40 Hotline, (Refer to Support request) Manuals, 40 Service, 41 Service and support Internet, 41 Support, 41 Support request, 41 Technical support, 41 partner, 41 personal contact, 41 SITRANS WFS300 Operating Instructions, 03/2021, A5E32880243-AC...